- (714) 578-6016

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

Worldwide Pricing and Secure Global Shipping Available!

- Get a QuickQuote

- Free Consultation (714) 578-6016

- Track Order Sorry, no orders are open for tracking

- Home

- RXPert Double Filtered Balance Systems by Labconco

Product Group:

9082-PP-01

9082-PP-01 71394

RXPert Double Filtered Balance Systems by Labconco

Read more

Manufactured By: Labconco

Print

Want a quote quickly ?

Submit a QuickQuote requestProduct Details

Product Details

Product Details

- Negative-pressure, double-HEPA-filtered fume hood for non-sterile compounding of hazardous drugs

- Meets USP 800 requirements for non-sterile hazardous compounding

- Contaminated air passes through both HEPA filters before exhausting back into the room

- Both HEPA filters can be scanned for leaks and certified without removal from the hood

- Internal vibration-reducing supports isolate the blower motor from the work surface

- Clean-Sweep airfoils guide inward airflow to avoid creating turbulence inside the hood

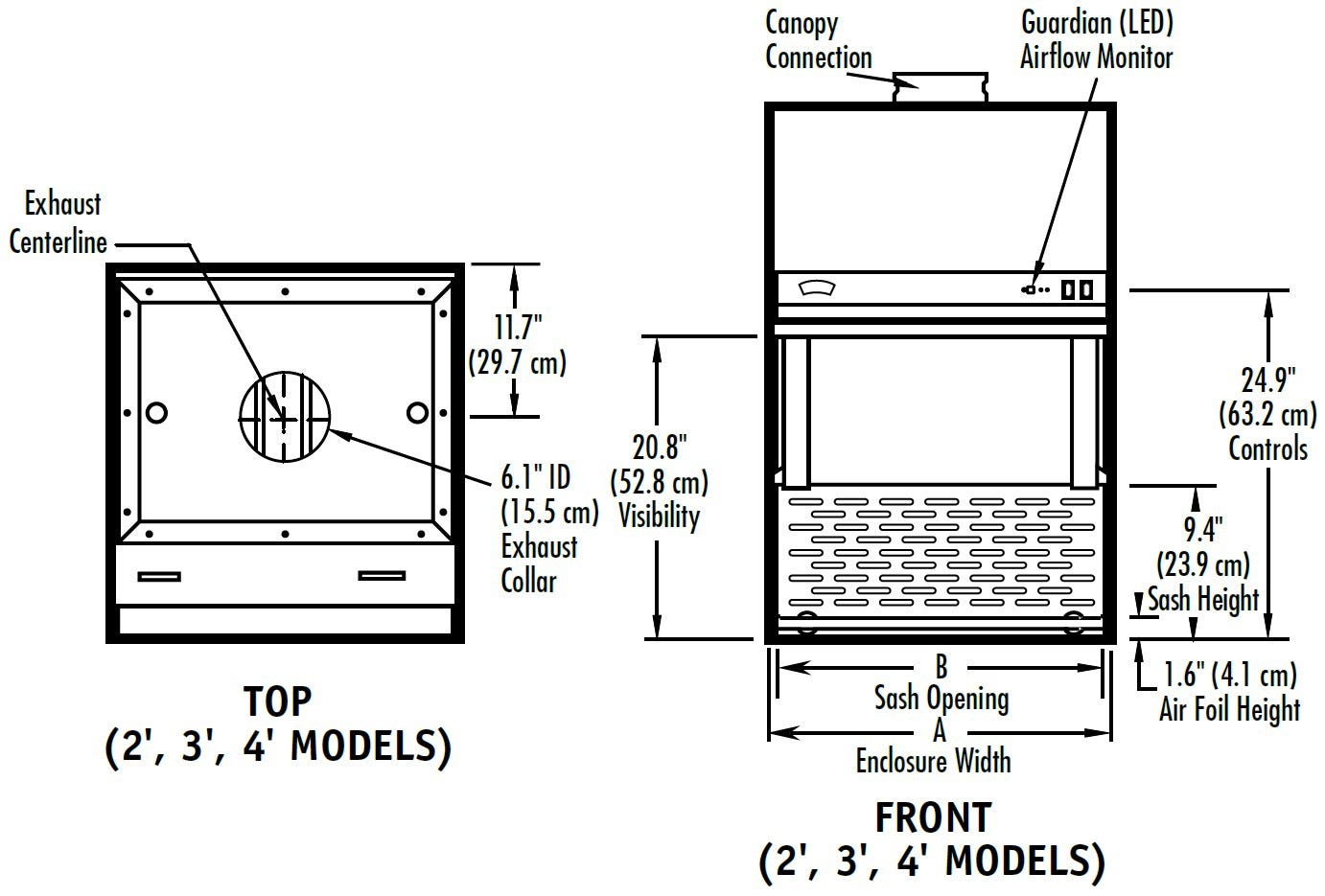

- Integral Guardian Airflow Monitor includes an audible low-airflow alert

- Filter backpressure gauge (left side) indicates remaining HEPA filter life

- Bag-in/bag-out system makes contaminated HEPA filter replacement safer and easier

- Static-dissipative coatings prevent powder from clinging to the glass and frame

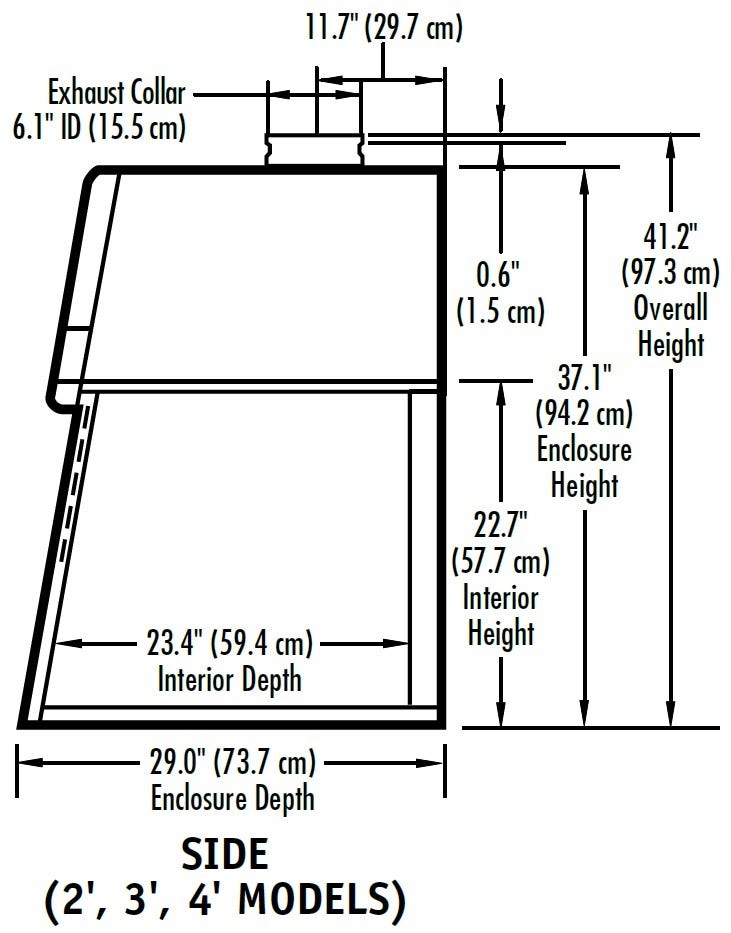

- 23.4” interior depth accommodates large balances and more equipment

- Two 1.5” utility ports provided along the bottom of the rear baffle

- Includes built-in fluorescent lighting (separate switches for blower and lighting)

- Work surface included on select models

Labconco RXPert Single Filtered Balance Systems

Labconco RXPert Single Filtered Balance Systems

The RXPert Single Filtered Balance System is a USP 800-compliant, Class I containment enclosure for non-sterile compounding of hazardous drugs | 9082-11 displayed Labconco RXPert Single Filtered Balance Systems Horizontal inward airflow protects the operators from airborne particulates generated by hazardous drug. The EXPert Single Filtered Balance System is ideal for ventilated enclosures when working in the pharmaceutical industry.

Features & Benefits

Features and Benefits

Bag-In/Bag-Out HEPA Filter Replacement

The bag-in/bag-out HEPA filter replacement system allows trained personnel to safely remove the dirty filters without risking exposure to harmful contaminants.

Containment Airflow

Negative-pressure airflow prevents contaminated air from escaping the enclosure, providing effective containment of hazardous powders and other particulates.

XPert Nano Enclosure Airflow

Labconco's Airflow Ionizer releases positive and negative ions into the hood that will neutralize static charges on the interior surfaces. Uncontrolled static allows powders and particles to cling to surfaces, creating a contamination hazard.

Available Accessories

Popular Accessories

For a full list of accessories, select a product then click Choose Accessories on that product page.

Labconco Corrosive Resistant Remote Blower

Labconco supplies coated steel blowers designed specifically for connection to Class I containment enclosures, including XPert, RXPert, Protector XVS, and Purifier HEPA Filtered Safety Enclosures. Explosion-proof versions also availableTelescoping Base Stand with Fixed Feet

Tubular, epoxy-coated steel frame base stands are adjustable to eight height positions in 1" increments from 27.5" to 34.5"; used with Labconco BSCs, hoods and enclosuresLabconco Balance Vibration Isolator

Labconco's balance vibration isolators minimize vibration when working with sensitive balances. Each isolator consists of a thick marble slab that rests on four isolator pads and a stainless steel cover that protects the surface.

Products similar to this one

Products similar to this one

- Group of 16 productsPurifier® Axiom™ Class II, C1 Biosafety Cabinets by Labconco FromAs low as $14,453Some ship in 17 - 23 days

Page 1 of 1

Other products you may find relevant

- Group of 8 productsSure-Grip® EX Undercounter Flammable Safety Cabinets by Justrite FromAs low as $1,136Some ship in 8 - 12 days

- Group of 10 productsSure-Grip® Flammable Liquid EX Safety Can Storage Cabinets from Justrite FromAs low as $1,120Some ship in 3 - 5 days

- Group of 21 productsErgoHeight® Electric Height Adjustable Cleanroom Workstations FromAs low as $1,707Some ship in 1 - 1 days

Page 1 of 6

Buy Accessories

Manuals & Resources

Manuals & Resources

PASSWORD REQUIRED

for

Labconco RXPert Single Filtered Balance Systems

| Nominal Width (A) | 2 ft. | 3 ft. | 4 ft. |

|---|---|---|---|

| Weight | 205 lbs. (93 kg) | 258 lbs. (117 kg) | 311 lbs. (141 kg) |

| Dimensions (W x D x H) | 24.0" x 29.0" x 41.2" (609.6 x 736.6 x 1046.5 mm) | 36.0" x 29.0" x 41.2" (914.4 x 736.6 x 1046.5 mm) | 48.0" x 29.0" x 41.2" (1219.2 x 736.6 x 1046.5 mm) |

| Electrical | 115V, 60Hz | 115V, 60Hz | 115V, 60Hz |

| Exhaust Volume (CFM) | 85 CFM at 60 FPM | 130 CFM at 60 FPM | 175 CFM at 60 FPM |

| 115 CFM at 80 FPM | 175 CFM at 80 FPM | 235 CFM at 80 FPM | |

| Lighting | Fluorescent | Fluorescent | Fluorescent |

| Filter System | HEPA (bag-in/bag-out) | HEPA (bag-in/bag-out) | HEPA (bag-in/bag-out) |

| Sash Opening (B) | 21.6" (549 mm) | 33.6" (853 mm) | 45.6" (1158 mm) |

| Conformance | ANSI Z9.5, CAN/CSA C22.2, Modified ASHRAE 110, SEFA 1, UL 61010 | ANSI Z9.5, CAN/CSA C22.2, Modified ASHRAE 110, SEFA 1, UL 61010 | ANSI Z9.5, CAN/CSA C22.2, Modified ASHRAE 110, SEFA 1, UL 61010 |

| Warranty | 2 years from date of shipment or 1 year from date of installation | 2 years from date of shipment or 1 year from date of installation | 2 years from date of shipment or 1 year from date of installation |

| Noise Levels and Exhaust at Varying Face Velocities | ||||||

|---|---|---|---|---|---|---|

| Nominal Width | 100 FPM Face Velocity | 80 FPM Face Velocity | 60 FPM Face Velocity | |||

| Exhaust (CFM) | db(A) | Exhaust (CFM) | db(A) | Exhaust (CFM) | db(A) | |

| 2 ft. | 145 | 53-58 | 115 | 50-55 | 85 | 48-53 |

| 3 ft. | 220 | 58-61 | 175 | 53-58 | 130 | 48-53 |

| 4 ft. | 290 | 62-66 | 235 | 58-61 | 175 | 49-54 |