Learn More: Gravity vs. Mechanical Convection

Gravity vs. Mechanical Convection Incubators

Incubators have traditionally been a mainstay for biological and life science laboratories, whether to grow or sustain biological cultures, reproduce germ colonies or breed/grow insects. The most basic incubators allow researchers to recreate precise temperature conditions for optimal growth, development and/or maintenance of finicky cells. Temperature homogeneity is also critical, as fluctuations in the living environment can be deadly.

As the fields of biotechnology and biopharmaceuticals have expanded, the demand for higher-precision incubators has increased. In addition, regulatory requirements regarding good-laboratory and -manufacturing practices (GLP and GMP) have been refined and intensified. Among other things, this has resulted in increased sophistication for cell culture control and monitoring. Additional instrument features bring additional cost, leaving many lab managers wondering if all the bells and whistles are really necessary for their applications

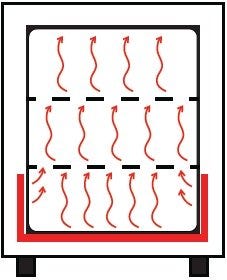

Gravity Convection

Heated air (less dense compared to cooler air) is introduced into the bottom of the incubator and gravity, causes the warmer air to rise and be distributed throughout the incubator. This airflow eliminates the need for a fan because gravity provides the force needed to distribute the air. Since less air is being displaced in the process of heating the instrument, samples are heated gently. This prevents them from drying out during incubations. Gravity convection technology is ideal for incubation of bacterial and eukaryotic cell cultures, but is limited by the degree to which air can be heated and the time it takes for an incubator to recover after the door is opened.

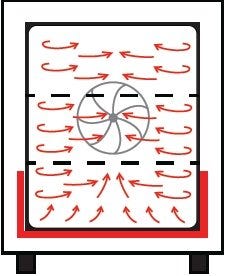

Mechanical Convection

Mechanical convection utilizes a fan to force heated air throughout the incubator, resulting in uniform temperature distribution throughout the unit. This method provides optimal temperature uniformity and stability due to the rapid distribution of air, which is ideal for bacterial cultures. In addition, mechanical convection can quickly warm samples that have been transferred directly from the refrigerator to the incubator. Since the movement of warm air over samples can lead to the evaporation of growth media, many laboratories utilize mechanical convection incubators to dry samples.

Dual Convection Technology

Dual Convection Technology combines the function of gravity convection and mechanical convection systems to create a high-performing, efficient and widely adaptable incubation platform. This adjustable fan speed allows users to specify operating parameters to optimize their individual experiments. When the fan is switched off, the evaporation occurring in the incubator is at its lowest. When the fan is set to 100%, the temperature stability and uniformity are optimized. Depending on the application, the speed can be adapted to provide optimal air flow for your valuable samples.