Learn More: Lab Oven Applications

The Types and Uses of Laboratory Ovens

Laboratory ovens address a wide range of applications in industries such as biotech, pharmaceuticals and materials manufacturing. These industries often require baking, curing, annealing and drying materials of varying chemical and physical compositions. Many of these process applications lead to unique results and require specialized lab ovens.

In general, most laboratory ovens have a temperature range from ambient to 300°C, which is sufficient for use in the fields of chemistry, biology and forensics. Ovens with temperature ranges above 300°C are typically reserved for more specialized operations in physics, materials processing and electronics. Regardless of the industry, several common processes are carried out with laboratory ovens.

Baking heats the substance without dehumidification. Pharmaceutical, manufacturing and material science labs will often use gravity convection ovens for this application.

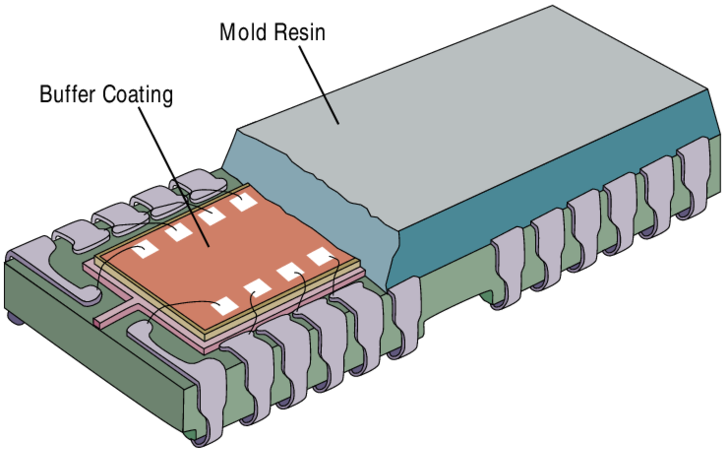

Polyimide baking is another common process carried out in gravity convection ovens. In stress buffer coatings, polyimide is added in liquid form and thermally baked to created a thin film on semiconductor components

Curing hardens the chemical composition of a substance through the combined action of drying and baking. This process is often used in the manufacturing of epoxies, glues, plastics and rubber in polymer research, nanotechnology and semiconductor industries.

Die-bond curing combines drying and baking within the oven to cure substances in order to harden their chemical composition. Examples include creating epoxies, glues, plastics and rubbers used in polymer research, nanotechnology and semiconductor industries. The increased bond strength is also exceptionally useful in adhering components directly onto circuitry used in military, space and medical systems.

Annealing heats and then cools material (glass or steel) for the purpose of increasing ductility. In contrast to hardening materials, annealing increases the strength of the compound, but allows it to retain a degree of flexibility. Applications in metallurgy, medical device manufacturing and material science industries use high-temperature ovens for this process. Stainless steel cleanroom ovens are used by the healthcare industry to anneal plastics onto syringes and catheters. In addition, annealing is used in biological applications to thermally couple a biological molecule to a membrane. This process is used in common laboratory techniques, such as a Northern or Southern blot.

Sterilizing heats materials to a temperature of at least 160°C, with contents monitored at this heat for 45 to 60 minutes. At this temperature, biological contaminants such as mold and bacteria are destroyed, resulting in sterile laboratory instruments, glassware or equipment.

Additionally, lab ovens are employed to perform material testing to analyze attributes such as tensile strength, deformation and resiliency of manufactured products, solder strength in circuit boards and more.

Lab ovens are also used in specialized biological, forensic and environmental labs. In forensic labs, specially configured vacuum ovens are used to develop fingerprints, while biological labs use gravity convection ovens to remove microbiological contaminants in lab equipment, along with vacuum ovens in order to adhere substrates to the surface of filters. Elsewhere, environmental laboratories weigh specimens before and after drying to determine their moisture content.