Learn More: Acrylic Vacuum Chambers

More Information

- Ideal for degassing small parts and mixed liquids, vacuum encapsulation, and general purpose vacuum experiments

- Provide a safe, convenient way to transport moisture- and particle-sensitive materials

- Clear acrylic construction provides full visibility of parts

- Sturdy construction and inlaid O-ring seal supports vacuum level down to 29.9" Hg (see ordering tables for vacuum capacity of each model)

- Solvent welding, 304 stainless steel and chrome-plated hardware ensure a completely noncontaminating environment

- Call to discuss custom sizes and applications, including installation of cable feed-throughs

These economical vacuum chambers provide a safe, reliable means for transporting contamination- and moisture-sensitive parts. They are also ideal for degassing operations, biological tests, material testing and other processes requiring sustained low and intermediate vacuums.

Cleanroom-Compatible Construction

Seven different sizes are available; all support vacuums to 29.9" Hg. All models are fabricated of transparent 1" (25 mm) thick acrylic, 0.52" (13 mm) acrylic on No. 5235-08. They feature chrome-plated latches to ensure a noncontaminating environment.

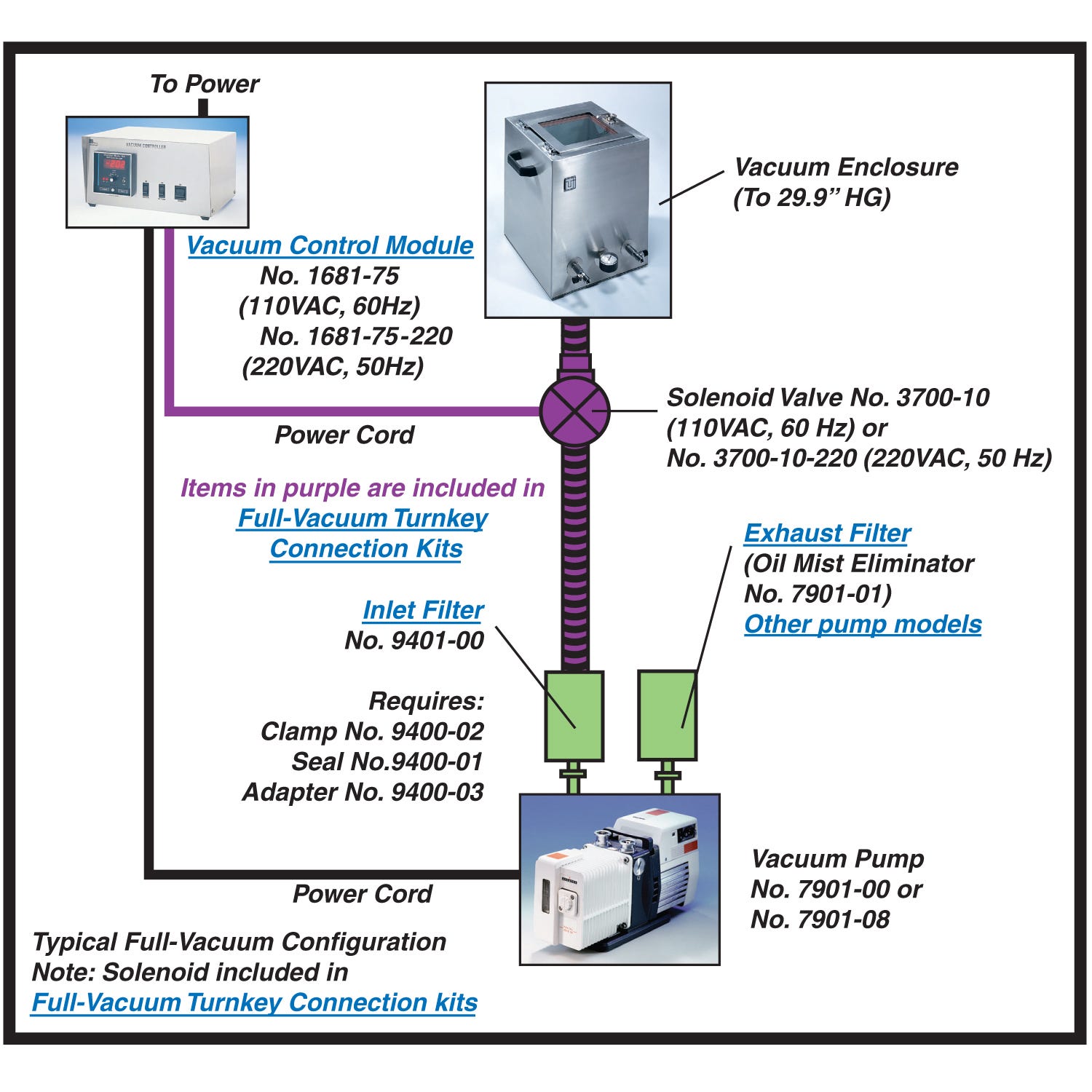

Terra installs a vacuum gauge and two metering valves to permit flushing of the chamber with purge gas before application of vacuum. Terra also features a full line of vacuum/nitrogen pumps. Recommended pump and accessories.

Note: Due to the inherent permeability of plastic, these chambers will not maintain a stable vacuum level over extended periods. For long-term vacuum maintenance, leave vacuum pump connected and running.

Why so Thick and Heavy?

Although your application may not require vacuum levels to 29.9"Hg, Terra builds its chambers to support this vacuum level due to safety concerns.

Variations in operators and operating protocol may lead to inadvertent spikes in vacuum pressure. Because these chambers are small, a few moments of vacuum operation beyond your target vacuum can subject them to substantially higher stress than you intend. Even a safety release switch is no guarantee that a chamber won't experience high vacuum pressure since these valves are not tamper-proof.

The best way to guarantee the safety of your parts and personnel is to use a chamber designed to sustain high vacuum levels. That's why Terra fabricates these chambers of 1"-thick acrylic.

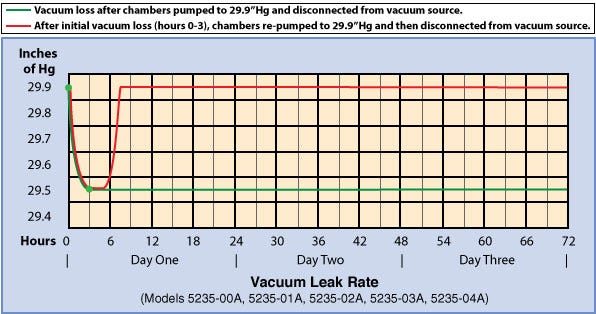

Vacuum Leak Test, 0-72 hours

Chambers lose vacuum pressure initially due to air released from acrylic walls during first three hours. If vacuum level of 29.9"Hg is restored following this initial drop in vacuum pressure, chambers hold 29.9"Hg with no detectable change in pressure over duration of test.

Aluminum vs. Plastic

Terra offers chambers in both materials. Which is right for your application?

- Acrylic Chambers

- Economy: Lower material cost translates into a less expensive chamber.

- Full visibility: You can add windows to an aluminum chamber, but nothing beats the 360-degree visibility offered by acrylic.

- Aluminum Chambers

- Chemical resistance: Aluminum stands up to Spor-Klenz®, alcohol and other sterilants, making it preferable in many bio/pharmaceutical applications. In addition, because many joining and sealing compounds are designed for use with metals, they may degrade acrylic and result in leaks or chamber failure.

- Greater machining versatility: Aluminum allows easier addition of feed-throughs to accommodate power and data cords, electrodes and other accessories. These add-ons are more feasible on aluminum than acrylic chambers, which are more prone to cracks that develop into leaks over time. For such applications, an aluminum chamber is a wiser long-term processing solution.

- More effective moisture barrier: Acrylic, because it is hygroscopic, allows moisture penetration on a molecular level. Under vacuum, these water molecules are released from the surface and may require several vacuum cycles to remove. These issues don’t occur with aluminum and other metallic moisture barriers.

- Greater dimensional versatility: Due to greater strength, aluminum is more appropriate than acrylic for larger chamber sizes.