Learn More: Gravity vs. Mechanical Convection

Additional Features

- Auto-dry function saves energy by turning oven off when samples are dry (need optional temperature sensor to use this feature)

- Door alarm notifies user when door is left open (for large capacity models)

- Optional independent sample sensor shows exact sample temperature (sample sensor is optional)

- Controller can be programmed for temperature ramps and dwells

- Compact footprint/volume ratio, saves energy; benchtop units are stackable

- Temperature accuracy over time ensured by simple calibration routine

- Boost function on benchtop models speeds up heating process and eliminates the need to operate oven 24/7 (feature not available in large capacity units)

- 180° door opening allows for easy access of samples and easy cleaning

- Access ports can be used to connect sensors for independent data monitoring

- Large fluorescent display for clear viewing

- Easy to use microprocessor-based touch button controls

- Automatic over temperature alarm system protects samples

- Option to use exhaust vent as access port for external temperature sensor

- Easy to clean smooth inner casing with rounded corners

Gravity vs. Mechanical Convection

Gravity convection involves gentle drying and heating with low air turbulences ideal for working with materials that are sensitive to airflow such as powders and foils. These units protect delicate samples while offering temperature uniformity of ±4°C with temperature stability of ±0.4°C at 150°C.

- Provides temperature stability of at least±0.3°C at 150°C and temperature uniformity of±2.9°C or better

- Low turbulence gentle heating and drying of material sensitive to airflow

- Ideal for gentle drying applications: electronics, pharmaceutical preparations, soil, sand, powders, paper and textile

- Ideal for curing paint adhesives, plastics and metals; vulcanization of rubber; heated storage of pills and drugs

Mechanical convection is suitable for faster sample drying and heating with superior temperature uniformity of ±3.3°C with a temperature stability of ±0.3°CC at 150°C.

- Provides temperature stability of at least±0.2°C at 150°C and temperature uniformity of±3.0°C or better

- Ideal for drying of powders and other application-related airflow with adjustable fan speed

- Delivers optimal temperature distribution

- Quick drying of glassware, powders, paper and textile

- Fast temperature recovery after door is opened

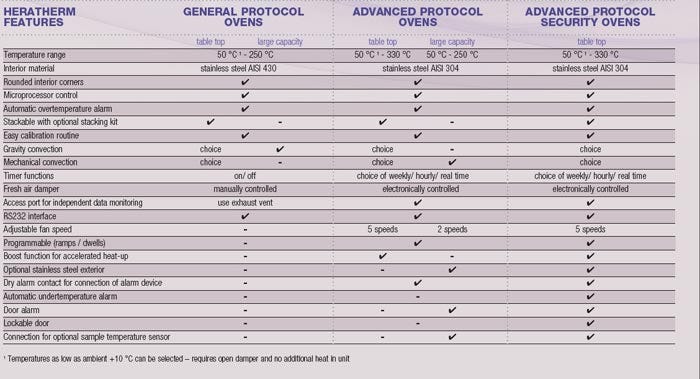

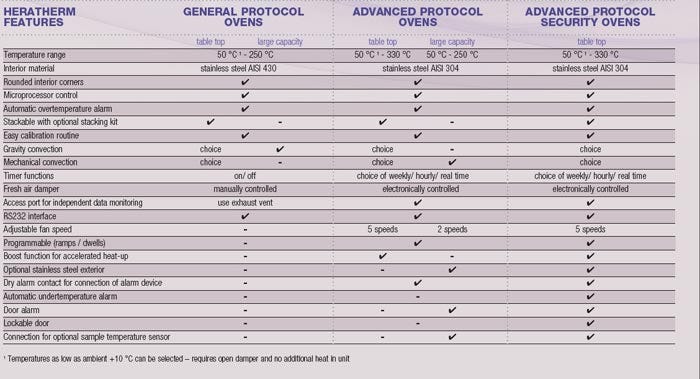

| Controller | Programmable Microprocessor control with vacuum flourescent display |

| Material | Corrosion-resistant stainless steel (AISI 304) inner chamber |

| Timer | On / Off, Recurring weekly, or real time |

| Temperature Range | - 50° to 330°C (60, 100, 180L)

- Ambient +10° to 250°C (400, 750L)

|

| Max Shelf Load | - 25kg (55 lbs.) (60, 100, 180L)

- 40kg (88 lbs.) (750L)

|