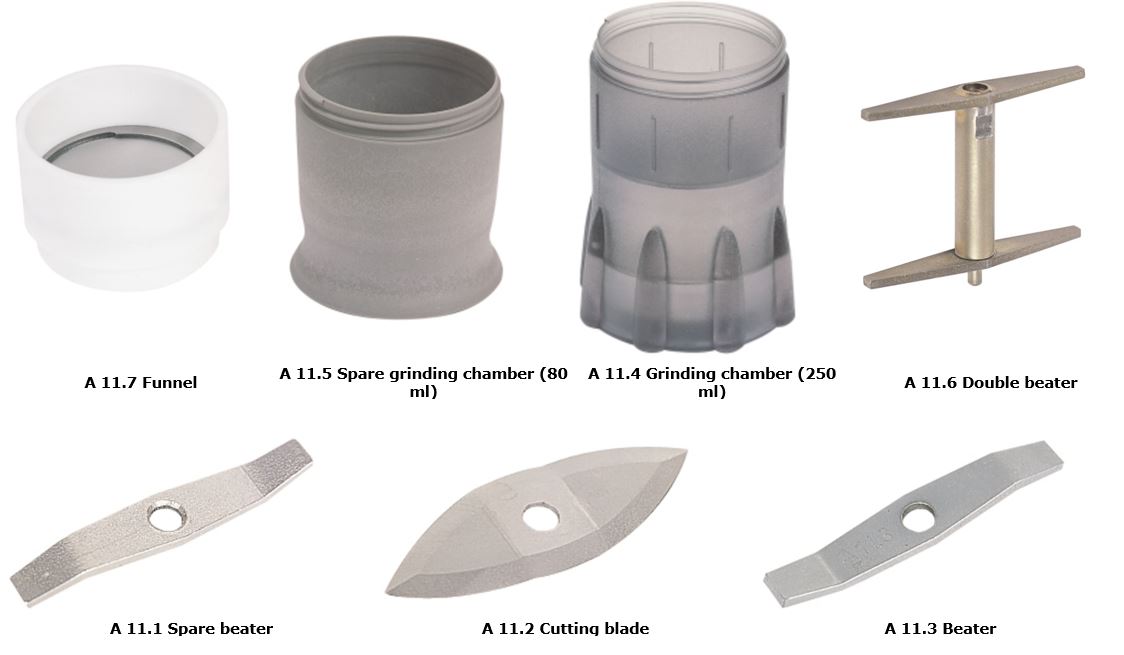

Learn More: A 11 Mill Accessories

Available Accessories for A 11 basic Analytical Mill

To ensure maximum particle size filtering, materials being processed are passed through a sieve prior to being discharged. Materials can then be collected using an NS 29 standard ground vessel. Sieves (sold separately) are available in sizes from 0.25 mm to 4.0 mm.

Grinding Procedures of A 11 basic Analytical mill

Impact Milling

- Grinds materials with hardness greater than 4 Mohs when used with A 11.3 beater

- Beating rotor reduces grinding material (must be reduced to 1 cm (feed granularity 10 mm—size of grain of corn ideal)

- Breaks up hard, brittle grinding material, dried material or material brittle from cold

- Granularity of final product determined by duration of grinding, amount of product and physical properties of material

- Types of materials processed: Grain, barley, corn, malt, pectin, roasted coffee, bark, roots, nutshells, bones, ergot, compressed materials, peat, cellulose, pharmaceutical, artificial, fertilizers, feed materials, spices, resin, potash, seeds, salts, slag

- Tough grinding material must be cooled with dry ice adding to grinding container

Cutting Milling

- Reduces bulk, elastic fibrous and soft materials with high cellulose content when used with A 11.2 cutting blade

- Rotating blade cuts grinding material

- Introduces less heat into grinding material

- Granularity of final product determined by duration of grinding, amount of product and physical properties of material

- Types of materials processed: Leaves, fibers, spices, grain, hops, cardboard, paper, hay, plastics, tobacco, peat, feed goods, dough and roots (feed granularity should be no greater than 10 mm)

- Added water should not be filled to more than 50% capacity

Cooling Processes for A 11 basic Analytical Mill

Dry ice cooling (CO2): approx. –78 °C

- Do not use A 11.4 grinding beaker (250 ml made of polycarbonate); beaker will break during cooling process

- Add dry ice after putting feed product into grinding beaker

- Prevent high pressure from building up in grinding chamber by waiting until dry ice is completely vaporized before attaching the drive

Liquid nitrogen cooling (N2): approx. –196 °C

- Use beater (A 11.1 or A 11.3)

- Do not use A 11.2 (blade becomes blunt quickly)

- Pour feed product into grinding beaker then pour liquid nitrogen with use of suitable Dewar vessel to ensure sample is completely submerged or covered

- Prevent high pressure from building up in grinding chamber by waiting until liquid nitrogen is completely vaporized before attaching the drive

- Use filling funnel A 11.7 to pour in liquid nitrogen