Learn More: Tube Mill Grinding Chambers

6-Step Process and Easy Storage of Tube Mill Control Grinding Chambers

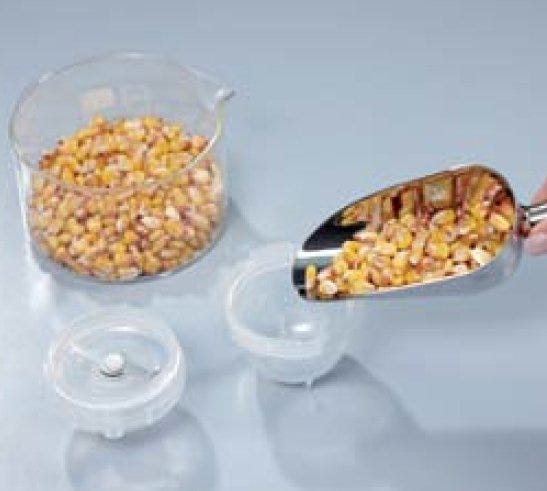

1. Fill grinding chamber

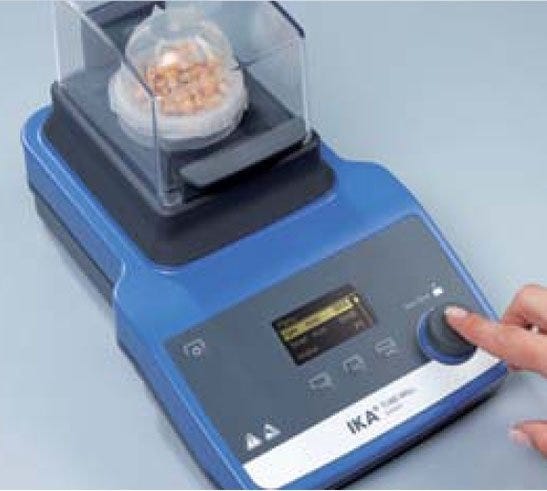

2. Place in Tube Mill and turn clockwise

3. Press to start

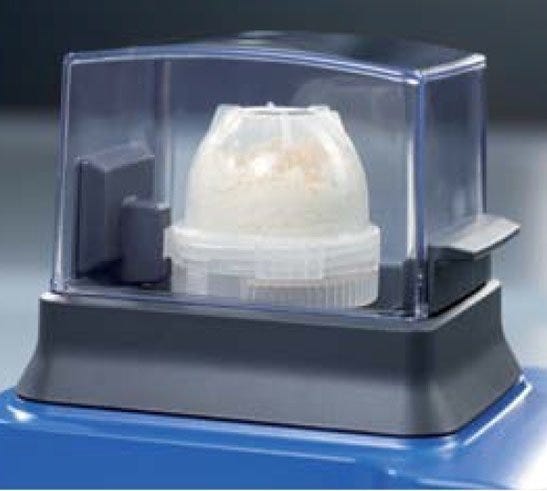

4. Clear cover allows full view of sample

5. Lift top and remove grinding chamber

6. Remove sample

Applications and Industries for IKA Tube Mill Control

- Food rice, wheat, cobnut, coffee beans, seeds, chocolate (with dry ice), parsley and spices

- Pharmacy vitamin tablets, tea leaves, glauber salt, blond plantain, sour orange paring, hawkbit roots, calamus roots and pastilles (with dry ice)

- Cosmetics color pigments, rubber benzo and bees wax (with dry ice)

- Chemical Industry rubber, molecular sieve, PE and PET flakes

- Biology tobacco, fresh ginger (with dry ice), leaves (with dry ice) and grass (with dry ice)

- Renewable Energy wood pellets, woodwoll + wax, straw, solid recovered fuel pellet, tetrapack, charcoal and chipped wood

- Medicine and Forensics chicken bones, chicken skin (with dry ice), pig craw (with dry ice)

- Building Material Industry marble and gypsum

Tube Mill control Cryo Grinding with Dry Ice

Moist, fatty, fibrous and resilient samples can be embrittled by adding dry ice directly into the grinding chamber. This creates an insulating effect within the chamber with minimal use of dry ice allowing the operator to handle the grinding chamber easily.Type of application samples embrittled with dry ice

Chocolate, bread, nuts, soil samples, gummy bears, leaves, meat, sausages, some plastics, bones, beef, feedstuffs, tobacco and grass

Put dry ice and material inside grinding chamber

Tube Mill Control shown with dry ice inside Disposable Grinding Chamber

Close lid and process