Learn More: Reach-In CO2 Incubators

More Information

- Leveling feet provides stability and added safety

- Airflow prevents product desiccation

- Easy to configure and use; audible/visual alarm and alarm silence; remote alarm contacts and available data outputs connects to in-house monitor/alarm to track chamber conditions (helps with meeting internal and regulatory documentation requirements)

- Data outputs help meet internal and regulatory documentation requirements

- Built-in features eliminate need for expensive add-ons

- Interior Dimensions (W x D x H): 31 x 27 x 60 in. (787 x 686 x 1524 mm)

- Exterior Dimensions (W x L x H): 38 x 33 x 80 in. (965 x 838 x 2032 mm)

- Available accessories, built-in gas guards, factory-installed data outputs, 2-stage gas regulators and shelves

- Humidity System: 15.1L pan

- Relative Humidity Range: Off, med. >80%, high >90%

- Temperature Control: ± 0.1°C

- Temperature Uniformity: ± 0.3°C at 37°C

- Temperature Range: + 5°C above ambient to 60°C

Cell Roll System

The optional cell roll system (shown installed within the incubator chamber) allows extensive production of monolayer cell cultures in standard roller culture vessels.

- Improves oxygenation and exposure of the cells to the media growth area

- Increases culture yields by the uniform temperature control and cellroller system's continuous, gentle rotation

- Accommodates a cell roller up to 7 decks high with 5 positions per deck—maximum total of 35 positions or bottles.

- Requires three tier models 4862 or 4868 to achieve maximum capacity:

- three tier cell roller base (15 positions)

- four add-on tiers (20 positions)

- and a reinforced floor/ramp to achieve

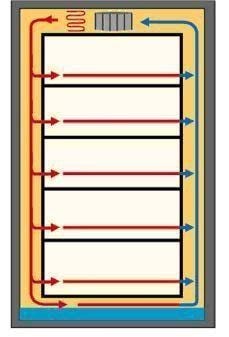

Directed Horizontal Laminar Airflow System

- Promotes ideal growth environment by releasing positive pressure feed plenum on the left side of the chamber and a negative pressure return plenum on the right side

- The combination of airflow directs air across the surface of each solid shelf

- Each shelf receives a consistent flow of conditioned air when filled with samples or equipment

- Chamber contents will not block feed plenum

- Minimizes risk of product desiccation and loss

- The directed airflow saves time and money by minimizing the risk of product desiccation and loss

Applications for Heratherm Advanced Protocol Security Microbiological Incubators

- Clinical and Medical labs: microbiological diagnostic testing

- Pharmaceutical: quality control testing, safety and testing efficacy of manufactured products

- Food: screening for bacterial contamination

- Research and biotech labs: bacterial growth, gene expression studies, production of recombinant proteins