Learn More: Germ-Free Hand Dryers

Fast, Safe Drying Where Tiny Particles Create Big Problems

In a particle-sensitive environment, PureDry™ helps to eliminate contamination problems by reducing the number of airborne particles and germs that can settle on PC boards, chemical solutions, biological cultures, and other sensitive materials.

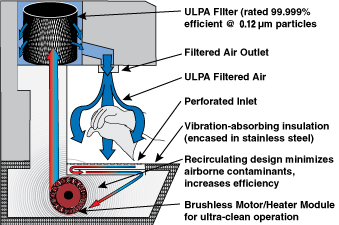

Unlike conventional drying towels, it ensures fast, thorough drying without contact with foreign media that can shed particles and harbor germs. A brushless motor eliminates carbon contaminants for ultra-clean operation. Its upstream heater warms the air stream before it passes through an ULPA filter and on to the drying area. This noncontaminating operation is especially crucial in cleanrooms and bio-cleanrooms that call for strict environmental controls. The PureDry also eliminates waste disposal and/or laundering costs associated with towel drying.

Select the germ-free recirculating air design to minimize turbulence that can adversely affect cleanroom air circulation and contain particles that may fall from hands or gloves. As the heated, filtered air stream passes downward, it is captured in a collection area (along with moisture and contaminants) and routed back through the heater/filter/blower module. This model thus has almost no impact on the cleanliness, moisture level, or air flow of the surrounding area. And outside air—a potential source of contaminants—is not drawn into the PureDry's filtered airstream. As such, the filter lasts the lifetime of the dryer.

The wall-mount, single-pass design offers the same ULPA filtration and advanced clean motor technology at lower cost. It also eliminates the chance of water droplets that fall from hands to be drawn into the make-up air flow, minimizing the risk of fouling the filter. Filter replacement is suggested every six months to maintain cleanliness. On both units a photo cell allows hands-free operation, and the extended exposure area of the PureDry provides ample space to dry elbow-length gloves. The all-stainless steel housing is compatible with cleanroom requirements. Its space-efficient design and low cost make it ideal for many applications, from pharmaceutical laboratories to semiconductor manufacturing plants to hospitals.

Hand Dryers or Germ Incubators?

We’re used to seeing standard hand dryers in a host of locations, from restaurants to research labs. Do they provide clean performance?

In most cases, no. In fact, they’re often more prolific sources of contamination, including microbial exposure, than paper towels. A June 24, 2014 Wall Street Journal article ("Paper or Power: Nothing Cut and Dried About Hand Washing in Restrooms") details the germ-laden issues common with most commercial hand-dryers.

The reason: non-filtered, high-capacity hand dryers concentrate contaminants inside motor, impeller and heating components. Potentially dirty room air is being draw into the dryer to blow directly on hands or gloves. Although heat may kill some germs, it is rarely hot enough, and exposure time is rarely long enough, to do the job effectively. In fact, the combination of heat and moisture inside the component housing often creates ideal conditions for incubation, turning standard hand dryers into germ factories.

Particulate or germicidal contaminants commonly exit the dryer in higher concentrations than they exist in ambient air. Worse, because hands or gloves are wet when they enter the airstream, contaminants may cling to surfaces, leaving them dirtier than they were before washing.

All things considered, a micro-filtered hand dryer is the only drying equipment that makes sense, particularly in a cleanroom, medical facility, or laboratory.

Terra’s Cleanroom Hand Dryers incorporate Ultra-Low Penetration Air (ULPA) filters rated 99.999% efficient at removing particles ≥ 0.12 microns in diameter. Effective micro-filtration, along with clean component selection and airflow engineering, makes these the ideal systems for cleanrooms from ISO 4 – 8.