Learn More: TSX Series Ultra Low Upright Freezer

More Information

TSX V-Drive Technology

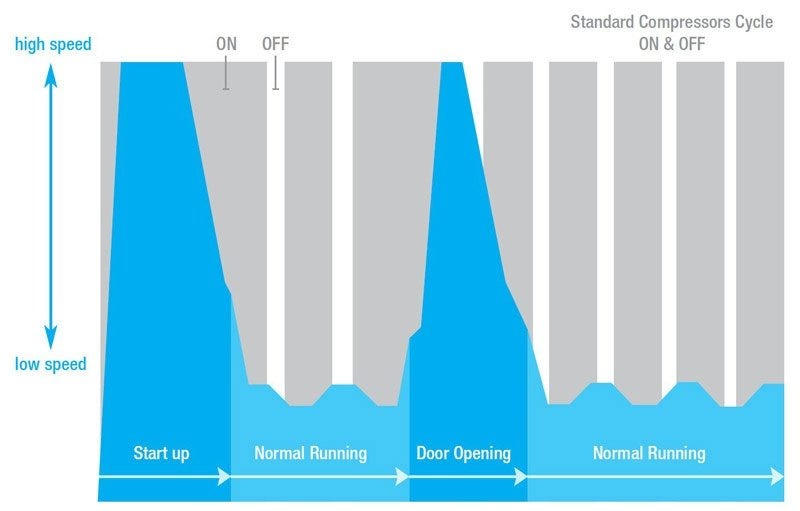

Variable speed compressors and adaptive controls adjust to both internal and external conditions. The control system detects multiple door openings (such as when adding samples to the freezer) and increases the drive speed to expedite recovery times. Once conditions stabilize, the compressors will slow down to the minimum idle speed to maintain the temperature setting, preventing wasted electricity. Two internal doors protect samples from temperature changes and reduce ice buildup, providing further energy savings.

A conventional ULT freezer has a single-speed compressor, requiring on/off cycles that increase wear-and-tear on the compressor, shortening its usable life span. The single-speed design slows door-opening recovery and wastes energy by inefficiently switching between maximum speed and zero.

Sustainability Features

- Dual hermetic compressors use natural, hydrocarbon-based refrigerants R170 Ethane and R290 Propane

- Water-blown foam insulation cuts down refrigerant out-gassing as foam ages

- Award-winning, zero-waste-to-landfill production facility recycles 93% of waste and converts 7% of waste into energy

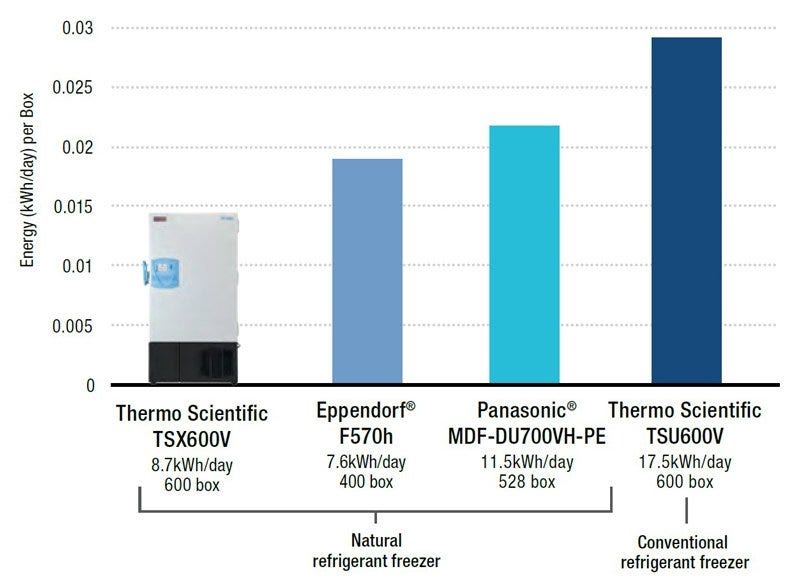

Natural, Hydrocarbon Refrigerants

The TSX Series employs hydrocarbon refrigerants due to their excellent thermodynamic properties, low Global Warming Potential (GWP) and zero ozone depletion. Hydrocarbon refrigerants are also better for the compressors, as they eliminate the lack of oil return associated with conventional refrigerants. The TSX-Series is UL and CE certified and adheres to the strictest safety standards.