Learn More: BSCs and BSLs

Biosafety Cabinets (BSCs) and Biological Safety Levels (BSLs): Breaking Down the Differences

What is a BSL?

Biological Safety Level (BSL) is a biocontainment designation developed by the American Biological Safety Association (ABSA) to protect personnel from exposure to harmful, potentially pathogenic microbes in a research or manufacturing environment.What differentiates BSL designations from one another?

In the United States, the Center for Disease Control specified four general Biosafety Levels, adopted from the ABSA designations. Each increasing BSL corresponds to greater risk, building upon the previous level to provide greater protection.

- BSL-1: for work with well-characterized microbes that do not present a serious health risk, such as laboratory strains of E. coli. This designation does not require engineering controls (i.e. a biosafety cabinet) and can be carried out on the bench with minimal personal protective equipment.

- BSL-2: for work with moderately hazardous microbes known to cause infectious diseases in humans. An example of this would be Staphylococcus aureus. This level requires the use of a biological safety cabinet with negative-pressure containment, and exhausted air must be filtered prior to release.

- BSL-3: for work with potentially lethal microbes that are easily aerosolized, such Mycobacterium tuberculosis. This level requires restricted access to the work environment, immunization of personnel (where available), and the use of respirators. Work must be performed in a primary engineering control such as a biosafety cabinet, and air must be filtered before it can be exhausted.

- BSL-4: for work with high-risk, airborne pathogens that frequently cause lethal infections, such as Ebola. Requires all work to be carried out in a Class III BSC. In addition, personnel must use full-body, positive-pressure cleanroom suits. All materials must be decontaminated prior to leaving the BSC.

Which BSC is appropriate to which BSL?

Biological safety cabinets were designed to provide localized protection from potentially biohazardous substances. In general, the BSL level corresponds to BSC class, indicating the BSC type most appropriate for each BSL application. The National Science Foundation designates three classes for BSCs:

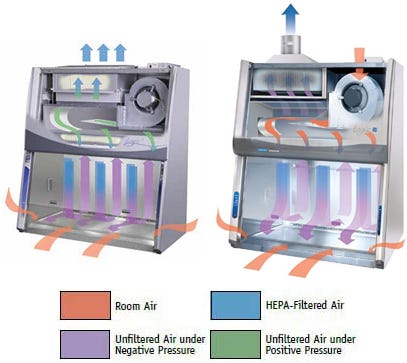

Biological safety cabinets were designed to provide localized protection from potentially biohazardous substances. In general, the BSL level corresponds to BSC class, indicating the BSC type most appropriate for each BSL application. The National Science Foundation designates three classes for BSCs: - Class I: a negative-pressure hood in which air is drawn from the room into the enclosure and subsequently exhausted after treatment with UV-C germicidal light and HEPA filtration. These enclosures protect personnel, but do not protect products within the hood.

- Class II: protect both operator and product. These units provide a HEPA-filtered laminar flow of air to protect the product from contamination, much like a laminar flow hood. Air is then directed into negative pressure plenums where it can be re-filtered or exhausted into a ducting system. Four common types of Class II BSCs are distinguished by air velocity as well as the percentage of air that recycled versus exhausted.

- Type A1 (formerly Type A): minimum inflow velocity of 75 ft/min. 70% of air is recirculated; 30% is ducted. The contaminated plenum is surrounded by the lab environment.

- Type A2 (formerly Type A/B3): minimum inflow velocity of 100 ft/min., with a negative plenum surrounding the contaminated plenum. 70% of air is recirculated; 30% is ducted.

- Types B1 and B2 have dedicated hard-ducted exhaust lines, with 70% air exhaust in Type B1 and 100% air exhaust in Type B2.

- Class III: provide the highest level of protection when working with high-risk pathogens. These enclosures are gloveboxes with airtight seals. Operators use glove ports to manipulate materials within the enclosure, never coming into direct contact with any materials. Exhaust air is HEPA filtered and directed into a ducting system.

BSCs, BSLs, and ISO Classes

When it comes to working with hazardous or potentially infectious material, protecting personnel must be the primary concern. However, offering personnel protection does not have to come at the cost of risking product integrity. Class II BSCs provide protection to both personnel and product simultaneously. They provide an ISO class 5 clean environment for product manipulation, while ensuring that exhaust air is filtered and ducted out of the environment. Thus, a class II BSC is the ideal solution when working with moderately hazardous material and both personnel and product safety are required.

When it comes to working with hazardous or potentially infectious material, protecting personnel must be the primary concern. However, offering personnel protection does not have to come at the cost of risking product integrity. Class II BSCs provide protection to both personnel and product simultaneously. They provide an ISO class 5 clean environment for product manipulation, while ensuring that exhaust air is filtered and ducted out of the environment. Thus, a class II BSC is the ideal solution when working with moderately hazardous material and both personnel and product safety are required.