Learn More: Dual Purge and NitroWatch Systems

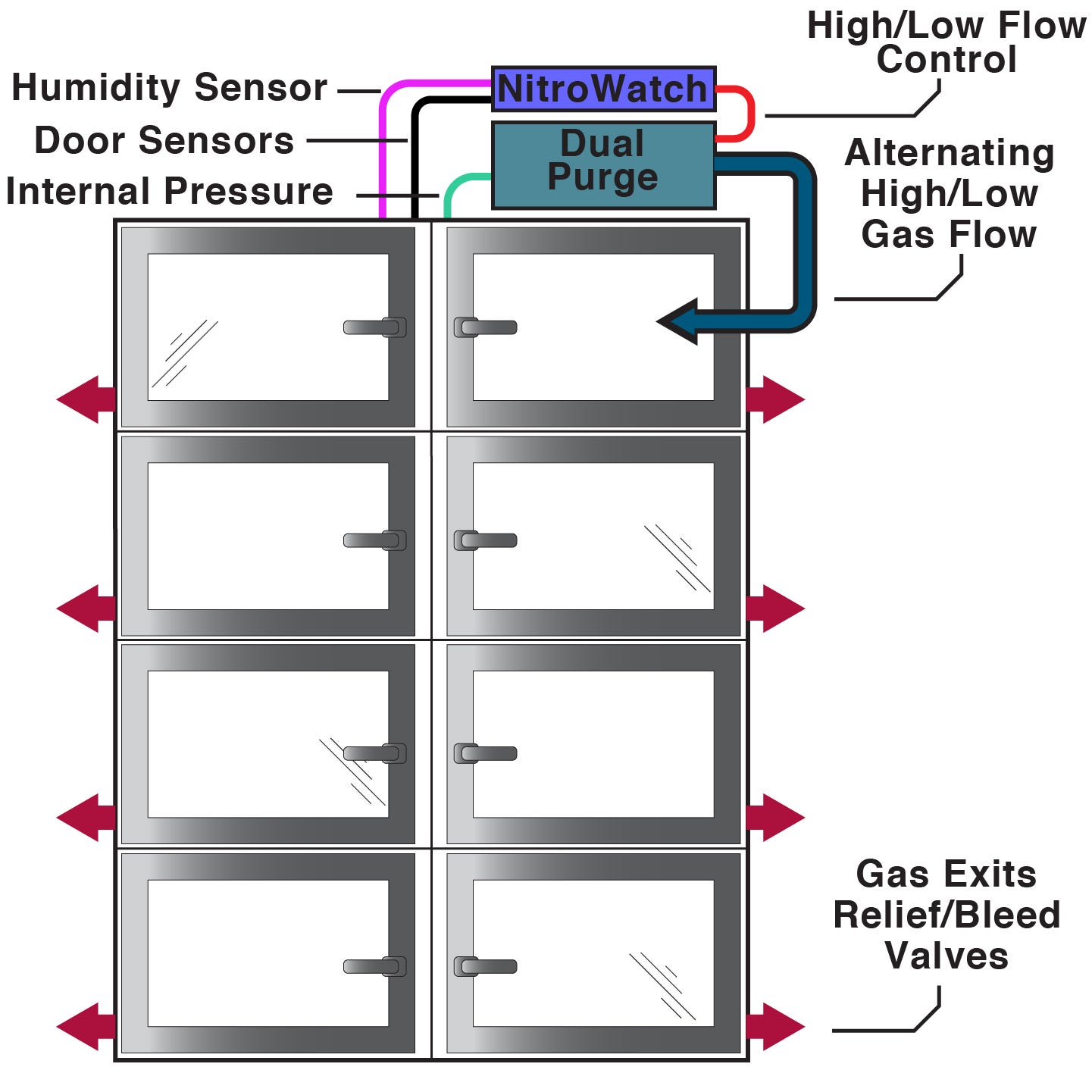

Dual Purge™ and NitroWatch™ System

- Cuts nitrogen waste, guards against oxidation

- Ensures a constant positive pressure inside desiccators and other enclosures to block contamination and moisture inflow

- Automatically activates high-flow purge when doors are opened to ensure fast, effective purge of particles and moisture

- Operates in tandem with NitroWatch® to maintain any desired sub-ambient moisture level (down to 0% RH)

- Guards against pressure damage to desiccator doors and seals

- Door switches are highly reliable—rated for over 10 million operations

Desiccators must be continuously purged with nitrogen or another process gas in order to ensure a controlled environment free of contaminants and moisture.

Unfortunately, however, a steady gas inflow can't guarantee the clean, dry conditions you require. A flow adequate to maintain a safe internal positive pressure when doors are closed is insufficient to overcome the backflow of outside air that occurs when a door is opened. A higher-level purge that might guard against this backflow wastes nitrogen and leads to over-pressurization that warp doors and damage seals.

Dual Purge System Offers Variable-Purge Security

The Desiccator Dual Purge System solves these problems by providing a higher flow level only when it's needed, and only for as long as it's needed.

It relies on a sensor switch installed on each door. During normal operation, with all doors closed, the system maintains an economical low flow of nitrogen into the desiccator to ensure a constant positive pressure of about 0.05" WG (Water Gauge)—just enough to block out moisture and contaminants.

When a door is opened, the sensor switch immediately activates a high-flow purge of nitrogen into the desiccator's plenum chamber that minimizes the influx of moisture and contaminants.

When the door is closed, the high-level gas flow continues to purge the desiccator for a selectable period of time, ensuring that any moisture that does enter the chamber is quickly forced out of the Automatic RB® (Relief/Bleed) Valve, before it can degrade sensitive materials. This time delay is adjustable, so you can retain the high-flow for a longer time when you suspect moisture contamination may have occurred. Note: The Automatic RB® Valve must be ordered separately.

The dual-purge capabilities of these units ensure that contaminants and moisture stay outside the processing chamber and at the same time guard against dangerous over-pressurization that can lead to warped doors, failed seals—even explosions! And because the Dual Purge System delivers only as much gas as is necessary, it economizes on nitrogen consumption; tests show that in many applications, these units can pay for themselves in a matter of months.

Safety Alarms Ensure Worry-Free Operation

The Dual Purge System incorporates a flowmeter, a line pressure gauge and a variable purge mechanism. A "Low-Pressure" alarm is activated if the incoming line pressure is ever interrupted. This dual audible/visible alarm alerts you to a disconnected supply line, an empty gas storage pod, or other problem that could spell disaster for contents of a desiccator or glove box!

NitroWatch™ Controller Expands Capabilities

The Dual Purge System operates in tandem with Terra's NitroWatch System to fully automate moisture control.

The NitroWatch includes a humidity sensor that continuously monitors the internal RH level and activates the Dual Purge to automatically maintain any sub-ambient humidity threshold you require (down to 0% RH). For more critical requirements, select the NitroPlex™, which combines this automatic humidity control with multiplexed purge capability. In all of these applications, the Automatic RB Valve is required to ensure safe relief of over-pressurization that can build inside a chamber.

The NitroWatch™ is available in two configurations:

- Smart® NitroWatch™ includes temperature sensing and built-in data logging (downloadable to a USB flash drive).

- Standard NitroWatch™ does not include temperature sensing or data logging.

Specifications

- Dimensions: 12"W x 11.25"D x 7"H (305 mm x 286 mm x 178 mm)

- Weight: 16 lbs. (7258 g.)

- Flowmeter: 0-20 SCFH

- Line Pressure Gauge: 0-60 psi

- Chamber Sensor: 0 - 0.4" WG (factory set at 0.02" WG)

- Inlet/Outlet: 0.25" (6 mm) (accepts 0.25" (6 mm) OD polyethylene tubing)

- Case Material: 304 stainless steel; Chrome plated or stainless steel internal fittings

- Power Requirement: 110/220VAC, 50/60Hz (requires no manual power setting)

- Timer Adjustment: 0-8 minutes (factory set at 1 minute)

Dual Purge™ Stand-Alone Operation

when Doors Closed

Moisture when a Door Opens

Dual Purge™ and NitroWatch™ Working Together

when Doors Closed and %RH Under Set Point

Moisture when Door Opened or %RH Under Set Point