A – Lab Incubator Capacity

(back to chart)

Laboratory incubators are manufactured in a broad array of sizes, ranging from compact benchtop units smaller than 1 cubic foot to high-capacity, reach-in chambers larger than 40 cubic feet.

Compact incubators (small-footprint, counter-top models under 6 cubic feet) are designed to house samples from a single cell culture line. For labs with limited workspace, certain benchtop incubators are compatible with stacking kits that accommodate up to 3 units.

Floor-standing incubators (up to 20 cubic feet) are designed to isolate cultures from multiple cell lines, protecting the samples from cross-contamination.

High volume reach-in models (larger than 20 cubic feet) include space for additional sample agitation equipment, such as incubator-safe shakers, for cell aeration and solubility studies.

Compare Incubator Sizes and Prices

B – Incubator Temperature Control Systems

(back to chart)

Lab incubators and environmental test chambers are designed to maintain environmental conditions ideal for growing and storing bacterial and mammalian cell cultures.

Why Use a CO2 Incubator for Cell Culture?

CO2 incubators, used primarily to promote human cell growth, maintain a temperature of 37 degrees Celsius and a humidity level of 95% RH. Microbiological incubators are designed to sustain temperatures between 5 degrees and 70 degrees Celsius to accommodate a variety of bacterial, viral and fungal species.

Refrigerated incubators maintain temperatures up to 40 degrees cooler than ambient conditions for fermentation studies and plant cell cultures.

C – Incubator Construction Material

(back to chart)

C1 – Aluminum Incubators

Drosophila incubators feature day/night cycling to promote fruit fly germination and include aluminum-clad interior panels for better light refraction throughout the chamber.

C2 – Epoxy-Coated Steel Incubators

Epoxy-coated steel resists the most common biocides and alcohol-based disinfectants, but may be prone to corrosion in high humidity environments.

C3 – Powder-Coated Steel Incubators

Powder-coated steel represents an economical alternative to stainless steel, resisting most sanitizers and disinfectants. However, the powder coating may crack after prolonged exposure to bleach-based cleaners.

C4 – Stainless Steel Incubators

Stainless steel incubators maintain aseptic conditions within the incubator, resist all sanitizers and disinfectants, and will not corrode in high humidity environments.

D – Environmental Incubator Air Convection Method

(back to chart)

D1 – Air Jacket Incubators

Jacketed CO2 Incubators employ two primary methods of temperature control: water-jacketed and air-jacketed internal plenums. Water-jacketed incubators offer better temperature uniformity but must be drained and cleaned weekly. Air-jacketed models are lighter, easier to transport, and maintenance-free.

D2 – Dual Convection Incubators

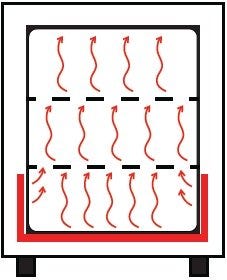

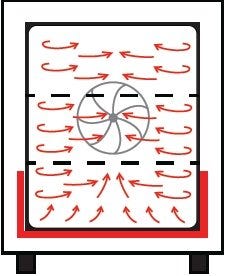

Dual convection incubators toggle between mechanical and gravity convection modes. Gravity convection models introduce heat, through a heating element, at the bottom of the internal chamber and allow gravity to cause the warmed air to rise throughout the storage area. Mechanical convection systems utilize an internal fan to distribute heated air across the internal chamber.

D3 – Forced Air Incubators

Similar to mechanical convection systems, forced air incubator utilize an internal or external blower to distribute heated air throughout the internal chamber. Forced air and mechanical convection incubators boast reduced recovery times after the chamber is accessed, making these designs ideal for high-throughput cell culture labs.

D4 – Gravity Incubators

Gravity convection incubators introduce heat into the bottom of the internal chamber and allow gravity to distribute the warmed air across the storage area as it rises. Gravity convection systems maintain lower air change rates than mechanical or forced-air units – ideal for labs storing non-aqueous samples prone to over-drying.

D5 – Mechanical Incubators

Mechanical convection incubators yield industry-leading temperature uniformity by utilizing a fan to distribute heated air across the internal chamber. Given their higher air change rate, mechanical convection incubators quickly warm samples transferred from cold storage without evaporating the growth media.

E – Voltages

(back to chart)

E1 – 120 Incubators

120-volt connections are suitable for standard residential power outlets in the US.

E2 – 240 Incubators

240-volt connections require less current (amperage) and smaller conductors than appliances designed to operate at 120V.

F – Special Application Features - Incubator Function in Microbiology

(back to chart)

F1 – B.O.D. Incubator Applications

Biological Oxygen Demand (B.O.D.) applications determine the amount of pollution within a water sample by quantifying the oxygen consumed by microorganisms as they decompose organic matter. BOD incubators utilize Peltier coolers to maintain precise temperature uniformity for wastewater treatment, germination studies and plant cultivation.

View BOD Incubator Specifications

F2 – Drosophila Culture Incubators

Drosophila incubators maintain optimal conditions for fruit fly culturing by incorporating day-night light cycling (through an internal LED light), Peltier thermo-cooling (for over-temperature protection), and mechanical convection (for rapid temperature changes).

F3 – High Security Incubators

High security incubators utilize restricted access controls, such as fingerprint scanners and keycard readers, to protect high-value samples for clinical diagnostics, recombinant protein production, or gene expression.

F4 – Small Footprint Incubators

Compact models with optional stacking kits are ideal for crowded research labs or educational institutions with limited benchtop space.

F5 – Incubators with Timed On/Off Cycles

For samples with incubation protocols beyond the standard 48-hour culture cycle, advanced protocol models include digital controllers with timed on/off cycles for real-time sample monitoring.

F6 – Incubator with UV Lighting

The two primary methods for incubator chamber disinfection are UV sanitization and high-heat decontamination. Germicidal UV light, emitted at 254 nanometers, denatures microbial genetic material. Incubators with UV lighting are equipped with digital controllers and load presence sensors to prevent samples from UV exposure. High-heat decontamination cycles utilize hot, moist air to sterilize the inner chamber when the incubator is free of samples.

F7 – Stackable Incubators

Certain benchtop incubators are compatible with optional stacking kits capable of housing up to three small-footprint units. Stackable units are ideal for crowded labs culturing distinct cell lines that cannot be stored within a single incubator.

F8 – Remote Cell Culture Monitoring Incubators

Incubators with remote cell culture monitoring systems allow real-time, visual sample observation through a mobile app or LIMS integration.

G – Cell Culture Incubator Humidity and Co2 Controls

(back to chart)

G1 – CO2 Gas Incubators

CO2 carbon dioxide incubators use infrared or thermocouple sensors to maintain optimal conditions for cell and tissue culture growth. Optional CO2 alarms alert operators when their gas tank requires replacement.

G2 – Cell Culture Incubators - Humidity Control Co2 Incubators

Eukaryotic cells grow optimally at a humidity level of 95% RH. Incubators designed for clinical diagnostics utilize infrared sensors to maintain precise humidity levels to promote human cell growth.

G3 – O2 Gas Incubators

For anaerobic cell culturing or hypoxia studies, certain incubators include O2 gas control to reduce oxygen levels within the incubator down to 0.1%.

Shop CO2 Incubators by Brand

Shop By Category and Incubator Accessories

Try before you buy!

DEMO MODELS AVAILABLE

Contact us for Demos, Samples, Brochures and more.

EMAILMon - Fri, 5:30am - 5:30pm PST