- Modular and flexible Microlab STAR Series for life science and diagnostic labs accommodate tip sizes from 10 μL to 5000 μL

- Provides smooth interplay between software, mechatronics and intuitive user interface

- Simplified workflow with VENUS Software and designed for easy integration of modules and devices

- Components and modules (sold separately): Labware gripper, pipetting channels, iSWAP Robotic Transport Arm, [MPE] Positive Pressure Module, Media Fill Module, housing extensions (see below for full details)

- Deck Capacity: 30 tracks (T) / 25 SLAS ANSI positions (STARlet), 54 tracks (T) / 45 SLAS ANSI positions (STAR)

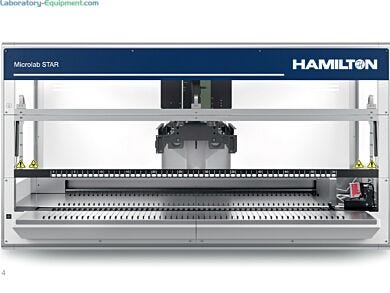

Modular Microlab STAR Automated Liquid Handler with a 54-track deck capacity; optional modules and housing extensions for application flexibility | 1017-17 displayed

Liquid Handlers & Robotics

1017-PP-06

1017-PP-06 80066

Microlab STAR Series Automated Liquid Handlers by Hamilton Robotics

Read more

Manufactured By: Hamilton

Print

Want a quote quickly ?

Submit a QuickQuote requestSelect Product Options

Summary

- Modular and flexible Microlab STAR Series for life science and diagnostic labs accommodate tip sizes from 10 μL to 5000 μL

- Provides smooth interplay between software, mechatronics and intuitive user interface

- Simplified workflow with VENUS Software and designed for easy integration of modules and devices

- Components and modules (sold separately): Labware gripper, pipetting channels, iSWAP Robotic Transport Arm, [MPE] Positive Pressure Module, Media Fill Module, housing extensions (see below for full details)

- • Deck Capacity: 30 tracks (T) / 25 SLAS ANSI positions (STARlet), 54 tracks (T) / 45 SLAS ANSI positions (STAR)

- Applications: Genomics, cellomics, diagnostics, forensics, proteomics, biobanking, drug discovery, industrial biotech

- Features:

- Color-coded status light at the front of instrument enables viewing of information such as progress of run

- Interior light provides clearer viewing of deck

- Modal Precision: x-y-z positional accuracy of 0.1 mm

- Noise Level: < 65 dBA, < 46 dBA in standby mode (according to EN 27779)

- Safety features and data management: Worklist Handling, Badge Number Tracking, Autoload with Tracking, Customizable Error

- Recoveries, Labware Reporting, Intelligent Pipetting, Bi-Directional LIMS Integration, Status Light, 2D-Barcode Reading

- Pipetting Technology:

- Monitored air displacement detects clots or empty wells with real-time tracking; useful in pipetting volatile solvents

- CO-RE II technology for improved tip attachment and precision, 15x life span, less wear and tear and lowers total cost of instrument ownership

- Dual Liquid Level Detection (LLD) detection in two modes: capacitive for conductive liquids and pressure-based for all liquid types (foaming liquids, organic solvents and non-conductive)

- Anti-Droplet Control (ADC) prevents inadvertent dripping by real-time detection and reaction to pressure changes from volatile organic solvents

- Total Aspiration and Dispense Monitoring (TADM)

- VENUS Software:

- Intuitive user interface provides basic and advanced programming and enables users full control of methods

- Power Steps enables easy assay set-up

- Five visual guides for frequently used pipetting tasks: sample transfer, add reagent, serial dilution, replicates and hit picking

- Color codes indicate type of tip used

- Shows important parameters at a glance

- Shows most common reason for errors to help save time and ensures smooth workflow

- Ambient Conditions:

- Temperature: +15º C - + 35º C (Operation); 25º C - + 70º C (Storage); - 25º C - + 70º C (Transportation)

- Relative humidity (non-condensing): 15% - 85% (Operation); 10% - 90% (Storage); 10% - 90% (Transportation)

- Overvoltage category: II (Operation, Storage and Transportation)

- Pollution degree: 2 (Operation, Storage and Transportation)

- Altitude: up to 2000 m/6561 ft. above sea level

- Processing time:

- 8 Pipetting Channels: Filling of one 96-well microplate with 100 μl sample (new tip for each sample) 320 seconds: Aliquot reagent to a 96-well microplate (<90 μl per well) 60 seconds

- CO-RE 96 Probe Head: Replication of one 96-well microplate: 100 μl, new tips, with cLLD on Aspiration 35 seconds; Reformatting of four 96 well microplates to one 384-well microplate: 50 μl, new tips, with cLLD on aspiration 140 seconds

- CO-RE 384 Probe Head:

- Replication of one 384-well microplate: 20 μl, new tips, with cLLD on aspiration 35 seconds; Reformatting of 4 - 384 well microplates to one 1536-well microplate: 10 μl, new tips, with cLLD on aspiration 140 seconds

- Options (sold separately):

- Functional Modules:

- Hamilton Heater Shaker for automated heating and shaking of ANSI/SLAS footprint microplates

- Hamilton Heater Cooler for precise temperature control for ANSI/SLAS footprint microplates

- Liquid Dispenser used for dispensing large quantities and/or aspirating liquid waste

- Cooling Carrier cools samples (predefined temperature) and identifies barcodes via Autoload

- Pipetting Channels:

- Individual channels for independent movement and asymmetric spreading

- Multi-Probe Heads: CO-RE 96- and 384-Multi-Probe Heads (MPH) for quick pipetting of 96 or 384-well plates, or partial plates

- Additional Options (sold separately):

- STARwatch service exclusively for STAR series models

- Additional status light at the bottom of instrument

- Housing Extensions keeps germs out and adds safety: slim right or left side, wide left side (for use with Multi-Probe Heads)

- Standard Carriers: tip carrier (holds five tip racks), plate carrier, tube carrier (hold up to 18 mm diameter tubes), reagent carrier, stacking carrier (stacks up to ten plates for increased deck capacity)

- Modules: Sky Frame (doubles capacity of filter tips and saves deck space), Multiflex MTP for microplates, Multiflex Stacker Module (stacks up to 10 microplates), Multiflex Active Plate Nest (exact positioning and fixing of microplates), Multiflex Tube/Cup Module (holds a variety of tubes)

Specifications

Other products you may find relevant