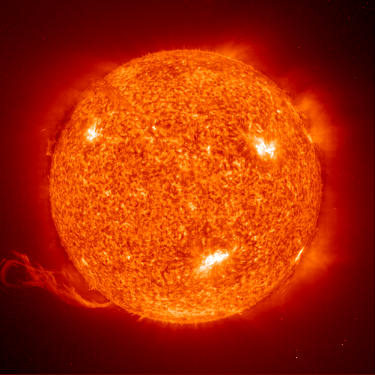

The sun naturally “cleanses” the earth’s surface with ultraviolet energy. Due to conditions like sun burns and skin cancer, we are most familiar with UVA and UVB rays, but there is actually a third classification of ultraviolet energy called UVC. These rays contain the highest energy, making them the most dangerous type of ultraviolet light. Fortunately, Earth’s atmosphere acts as a protective layer and UVC energy does not penetrate our ozone layer. These harmful rays, however, are industrially produced as a beneficial source of UVGI (ultraviolet germicidal irradiation). Keep reading to find out why.

How does UVGI work?

UVGI is a technique that utilizes short-wavelength ultraviolet light to kill microorganisms. Since UVC energy is not naturally present within our planet’s atmosphere, earth-bound microorganisms, such as germs or viruses, have not evolved to naturally defend themselves against the damaging rays. Ultraviolet sanitizing units mimic the sun by producing these high-energy wavelengths, killing up to 99.9% of germs without the use of chemicals.

Ultra-Violet Ductwork Sanitizers

Airborne particles that contain living organisms are responsible for about 60 to 80% of infection relating to indoor air quality. For this reason, heating, ventilation, and air conditioning (HVAC) maintenance is crucial to the well-being of clean room operations. High intensity UVC lamps can be installed in different duct sizes to ensure that microorganisms are eradicated from recirculated air.

Airborne particles that contain living organisms are responsible for about 60 to 80% of infection relating to indoor air quality. For this reason, heating, ventilation, and air conditioning (HVAC) maintenance is crucial to the well-being of clean room operations. High intensity UVC lamps can be installed in different duct sizes to ensure that microorganisms are eradicated from recirculated air.

Operation factors to consider

The type of organisms being targeted influences the UVC exposure rate needed. For ductwork in particular, the length of ducting is important to consider. Longer ducting creates more surface area requiring additional modules for effective UVGI exposure. Low, medium, or high air blower speeds will also affect the required number of modules and exposure for your application.

V-RAY™ Ultra-Violet Disinfection Modules

Individual UVC lamps can be installed inside small confined chambers, like glove boxes. Direct exposure to UVC rays will kill contaminating germs that are often missed in corners when wiping down a glove box interior. Whether it is permanently mounted or installed with quick connect fittings, this economical module provides fast-acting sterilization. Chambers possibly requiring sanitation include pass-throughs, desiccators, and fume hoods.

requiring sanitation include pass-throughs, desiccators, and fume hoods.

Operation factors to consider: Since UVC lights contain the highest amount of energy for killing microorganisms, human exposure is harmful. Workers must use personal protective equipment (PPE); face shields and goggles are highly recommended. Acrylic, PVC, and most glass provide shielding of UVC light, although ultra-violet energy does speed up the degradation of many plastics. UV modules are typically used for life science or biopharmaceutical applications. A common safety practice is to activate lights when personnel are off duty, reducing potential exposure.

Torch™ Portable UV Disinfection by ClorDiSys

For larger spaces with multiple surfaces needing sterilization from hazardous viruses, portable UV disinfection modules, such as Terra’s Torch™ by ClorDiSys, is an effective and economical solution. The mobile unit is constructed of eight quartz-glass low-mercury UVC bulbs. Positioned with an open center, the UVC bulbs provide 360-degree coverage for unusually shaped rooms. Its 4-degree tilt extends the light towards the ceiling. The Torch is especially useful for hospital rooms, healthcare facilities,  and labs; ambulances utilize them after being exposed to high-risk, infectious viruses like Ebola.

and labs; ambulances utilize them after being exposed to high-risk, infectious viruses like Ebola.

Operation factors to consider: When using portable UV disinfection for applications involving high-risk microorganisms, planning for adequate exposure time is vital. In some cases, using multiple units will minimize the occurrence of “shadow” areas (surfaces not in full view of the UVC light). It is also important to alternate placement of the unit for multiple exposure cycles. In hospital rooms, for example, beds must be exposed to the UVC unit multiple times on each side.

Unprotected personnel should not be in a room while a UVC light is active. Case Western Reserve University acknowledges that direct exposure to commercial UVC can cause severe skin burns, while excessive contact causes skin cancer. Cataract formation and retinal damage are expected when eyes are not guarded by a face shield; standard eyewear with open sides is not sufficient. Well-designed UVGI systems include an occupancy sensor that aborts operation if motion is detected. In addition to having this safeguard, the Torch Sensor Module features a remote control push button, manual reset button, as well as an emergency stop button.

Conclusion

The versatility and efficient sterilizing capabilities of ultraviolet germicidal irradiation makes it a reliable solution for countless aseptic operations. Depending on which form of UVC product best suits your application, there are safety protocols of which to be aware in order to ensure optimal performance and reuslts. For more information regarding UVGI, visit Terra’s UVC Systems page or give us a call! We have experts available to discuss your application’s specific needs.