Controlled environments act as secluded clean spaces for performing select applications in a manner that protects the internal samples or materials and/or the workers involved. Air pressure is a key component of a cleanroom. The internal pressure and, by design, the differential pressure, are closely regulated and maintained. Basic chemistry tells us that high pressure air has greater mass than low pressure air, and given the opportunity, will flow into the less dense environment.

Ascending or descending pressure differentials are part of the foundation of most controlled environments. Maintaining a specific differential between adjacent areas reduces the inflow of airborne particulates and/or prevents hazardous materials from escaping. The type of application dictates whether a positive or negative pressure space is required. So, how do these two pressure types differ?

Isolation vs Containment

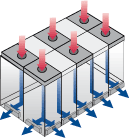

Positive pressure room showing air entering through ceiling filters and exiting from floor vents

Positive pressure rooms isolate products and personnel from outside, ambient contaminants. Air is drawn into the room through HEPA or ULPA filters that remove particulates. The amount of air entering is greater than the amount exiting. Lower-pressure outside air is unlikely to infiltrate the clean environment through doors or pass-through chambers; the higher-pressure air creates a barrier.

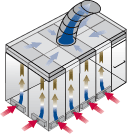

Negative pressure room with filtered air inlet and filtered venting through ceiling duct.

Negative air pressure contains and restricts hazardous contaminants from release into the outside room or the surrounding facility. A negative-pressure cleanroom continuously pulls more air out than what is coming in, creating a low-pressure environment. The exiting air may be fed through particle filters and/or activated charcoal filters (for fume or vapor removal).This ensures that any hazards originating from within the room are controlled. These cleanrooms often follow regulations governing biological safety levels (BSL) for protection against bio-hazards or toxic chemicals.

Why is pressure differential important, and how is it measured?

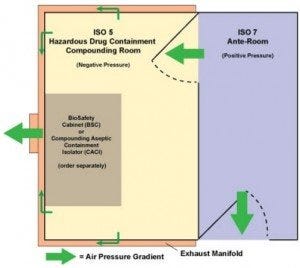

A high- or low-pressure work environment may not be limited to one space. For example, many pressure-controlled cleanrooms contain gloveboxes or hoods that are required to maintain their own pressure level with a minimum differential compared to the cleanroom (an ISO 5 glovebox within an ISO 7 cleanroom, as an example). The work area for the target application will always be the cleanest level, surrounded by intermediary “spaces.” This is referred to as cascading pressure.

USP 800 cleanroom showing different ISO levels (positive or negative pressure requirements) in each chamber

In the case of a positive-pressure multi-room critical environment, the cleanroom (or buffer room) will have higher pressure compared to the adjacent gowning room or antechamber, and the antechamber will have higher air pressure compared to the uncontrolled outside area. As an example, the pressure differentials between each level could be 0.02” Water Column (WC)–enough to create the “air barrier” that blocks the infiltration of contaminants. This escalating level of cleanliness ensures the highest level of protection for samples and personnel.

A differential gauge (such as Magnehelic®) measures filter resistance, fan and blower pressures, air velocity, and drops in pressure along cracks or openings. Within the gauge, an internal diaphragm separates two sealed regions with varying pressure. The amount of tension placed on the flexible membrane provides an air pressure reading.

While a Magnehelic gauge does not use liquid displacement to measure the pressure as is the case with a traditional manometer, the measurements are still referred to as “inches of water” (aka Water Column or Water Gauge). According to ISO, the recommended air pressure differential between spaces should be 0.02 to 0.05 inches water gauge (WG). Critical environment control systems ensure that required pressure differentials are recovered after doors are opened.

Sample Applications: How are these pressure-controlled areas used?

USP Compounding Aseptic Isolator (CAI): a two-chamber glovebox with filtered laminar air flow and dual Magnehelic gauges

Positive and negative pressure cleanrooms, gloveboxes and hoods are used by a variety of industries for tasks ranging from electronic production to research and development of vaccines and medications. During the manufacturing of semiconductors and circuits, for example, the smallest of particles can compromise a microchip. Without a positive pressure, filtered laminar airflow cleanroom, integrated circuits used in every-day devices would be ineffective.

Trace metal/element cleanrooms analyze chemical pollutants found in drinking water, wastewater, and ground water, and are regulated by the EPA (United States Environmental Protection Agency). According to an EPA article, an ISO 5 (Class 100) positive-pressure cleanroom is recommended for accurately testing samples.

USP compounding room showing ante chamber and buffer room. Pressure differentials are monitored and manipulated from the outer control panel.

Producing vaccines can be dangerous. As we’ve seen happen, careless treatment of viruses can have deadly effects. Vaccine production, as well as the R&D that supports their development, are typically performed in pressurized enclosures or gloveboxes. A positive pressure chamber maintains a clean, contamination-free environment for safely creating drugs and other substances intended for human consumption.

Highly contagious diseases, such as the Ebola virus, must be fully contained during treatment. Exposure to an infected patient places healthcare workers at risk. In this case, restricting contamination from the outside environment is less important than preventing exposure to the virus. A negative-pressure room ensures the safety of hospital staff and all who work in the surrounding facility.

The list of potential uses for positive- and negative-pressure climates continues to grow. Research and manufacturing facilities must keep up as technology progresses and regulations become more demanding and complex. In some cases, the progression of cleanroom technology has opened new doors for research and manufacturing. Pressurized critical environments have played a large part in the development of science over the last few decades, and will continue to do so.

Read more about positive and negative pressure work environments as they apply to various applications: