Cleanroom entrances present a significant potential for contaminant infiltration, so they must be managed with this in mind. Air showers are one way to minimize piggy-backing contaminants. They are enclosed chambers that use strong bursts of air to dislodge particulates from people or transport carts entering or exiting the room. Room entrances, and pass-throughs that incorporate an air shower, serve as a safeguard between critical and non-critical areas. Personnel are the greatest source of contamination in a cleanroom, so most of the methods of contamination reduction, including air showers, were developed to accommodate humans. Air showers range in size and construction, depending on the application, and are utilized by a diverse range of industries. So, how do air showers work? Find out below!

Air shower design and operation

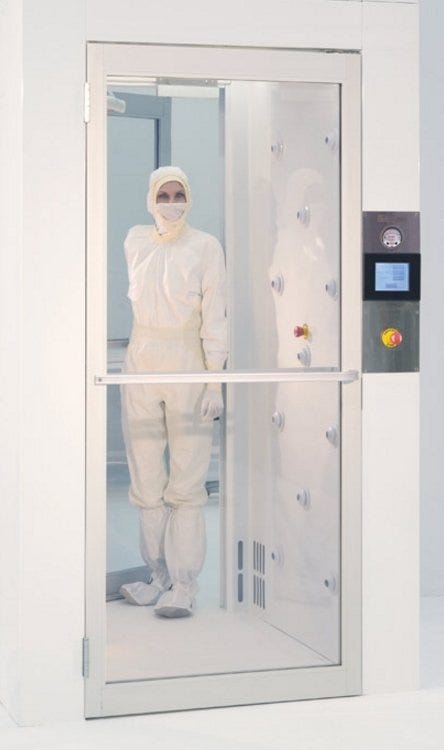

Modular air shower chambers and tunnels use high-velocity streams of HEPA- or ULPA-filtered air to dislodge surface particulates as personnel and/or parts enter the antechamber or buffer room. The self-contained motor and blower directs clean air into the unit through nozzles where personnel/parts are “scrubbed” by the accelerated air to remove unwanted contaminates. A closed-loop recirculating exhaust system then pulls the dirty air out of the unit through vents and wall plenums. The air, now laden with particulates, is routed through a HEPA or ULPA filter to be removed from the recirculated air. The air tunnel’s interlock system also minimizes inflow contamination by preventing users from opening both entry and exit doors simultaneously.

Facilities have different policies and cleanliness requirements. Some locations place an air shower at the entrance to a gowning room to reduce contaminants carried or generated by street clothes, prior to garbing with cleanroom apparel. Other facilities position the air shower between the gowning area and the cleanroom, for workers to enter after they complete the garbing process. Finally, many labs have a need for air showers at both the entrance and exit of a controlled room.

Are there different types of air showers?

Terra offers isolated single-person air showers and air shower tunnels, as well as various sizes of air shower pass-through chambers. An air shower tunnel is larger than a single-person air shower, allowing multiple workers to collectively enter/exit the controlled environment. Both the chamber and tunnel designs feature uniformly spaced nozzles that supply concentrated ISO 5 rated airflow with a velocity of up to 41 m/s (8,000 ft/min).

A wall-mounted or floor-mounted air shower pass-through chamber facilitates the efficient transfer of parts, materials and equipment from the “dirty” side to the “clean” side. By using a pass-through, personnel can reduce time and apparel cost associated with donning cleanroom garments in order to move items into the critical area. The particle-laden air is pushed out of the pass-through through a vent on the “dirty” side. Similar to the walk-in air showers mentioned, Terra’s pass-through chambers also feature the door interlock system and provide airflow velocity of 41 m/s (8,000 ft/min).

Air shower pass-through chamber

Who uses air showers?

While an air shower may not always be necessary, certain industries require strict sanitary environments. In order to preserve the required cleanliness level, anything entering the cleanroom must be free of particles.

During the production of semiconductors, for example, the highly sensitive integrated circuits (ICs or chips) are easily compromised by airborne contaminants. While several process are completed using machinery, personnel still play a vital role in IC production and have the potential to corrupt the chips’ integrity.

Pharmaceutical companies are held to high cleanliness standards due to their role in developing and producing drugs and medications. When working with lab animals, for example, air showers limit allergens from leaving the controlled space. If products are compromised during manufacturing, consumer health could be adversely affected.

Several other industries also utilize cleanrooms and require specialized regulations. Biotech companies utilize aseptic cleanrooms when researching biomolecular and cellular processes for developing new technology. High-precision optical equipment must be contaminant-free during the production of complex optoelectronic devices. Medical facilities perform specialized surgical procedures such as stem-cell transplants and gene therapy in cleanrooms; it is critical that doctors are decontaminated before entering the clean environment.

Openings are the most vulnerable areas of a cleanroom. A pass-through minimizes foot traffic which is a large contributor to contamination; however, personnel are still required to use doors to enter and exit the controlled environment. By adding air showers to “re-enforce” these openings, you increase the likelihood of successful performance of your applications.

See more about Terra Universal’s cleanroom Air Showers and Tunnels, with different configuration choices to fit your facility and workflow.