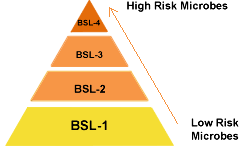

Biological safety Levels (BSLs) are prescribed by the CDC (Centers for Disease Control and Prevention) to inhibit contamination of a work environment and ensure worker safety by outlining operating procedures and atmospheric controls. If you’ve read the BSL guidance document, you may have found the infection-rate distinctions and cabinet classes hard to conceptualize. Here, we summarize section IV of the Biosafety in Microbiological and Biomedical Laboratories, 5th Edition.

There are four levels of infectious-agent exposure, each designated to abide by a specific set of control designs and protocol. To determine the safety control level, laboratories must consider several factors, including disease transmission and severity, infection potential, microbe or agent origin, and type of work. See “Biosafety Levels” below for a description of each level.

How do BSLs differ from standardized ISO levels?

ISO classes focus on measuring and regulating particle count, airflow velocity, and air changes, among other factors, to create a desired critical cleanliness level; Biosafety is a set of safety precautions that reduce the risk of exposure to, and transmission of, potentially contagious microbes while working with bacteria and viruses. While an ISO-rated room can exist without meeting BSL requirements, you cannot have a BSL-designated room without an ISO rating.

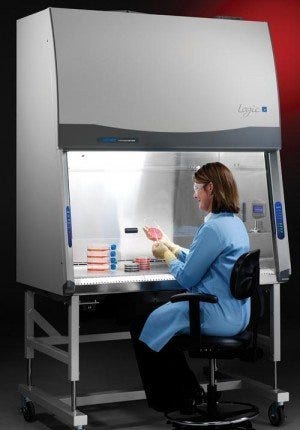

Another level of safety employed when working with higher-risk microbes in BSL cleanrooms are Biological Safety Cabinets (BSC). These are specialized enclosed work stations (hood or glove box) that act to contain hazardous biological samples. The specific biosafety level will dictate whether this additional equipment is warranted.

Biosafety Levels

The level indicates the amount of protection needed for safe operations. Each biosafety level builds upon the previous standard to provide an ascending degree of safety for personnel and the environment. Below is a summarized list of biological safety levels; see the complete list of criteria in this CDC document.

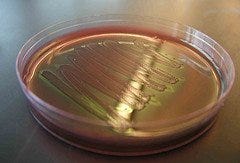

Figure 1: Petri dish containing E. coli

BSL-1 designates an environment for processing well-known microbes, such as E. coli, carrying low infection rates , and for which the potential hazard is minimal. Work can be completed on an open bench with basic PPE (Personnel Protective Equipment) and a door that separates the BSL-1 lab from the main facility. Biological safety cabinets are not generally used at this level.

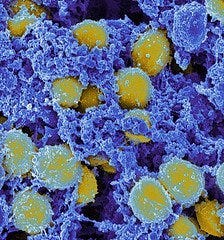

Figure 2: Staphylococcus aureus

BSL-2 is required when moderately hazardous microbes are present, e.g. Staphylococcus aureus or Clostridium dificil. Personnel should be specially trained for handling level 2 pathogenic agents. Self-closing doors contain the lab and restrict access while the lab is in operation. Moderate PPE is needed, including eye/face shields, and several tasks are performed in a BSC. In some cases, respiratory protection may also be necessary.

Figure 3: Mycobacterium tuberculosis

BSL-3 regulates labs where potentially lethal airborne microbes are introduced. These microbes are often “exotic” and include pathogens such as tuberculosis. Although highly infectious and easily communicable, antidotes are readily available for these biological agents. Personnel should not only be specially trained for handling parasitic agents, but also potentially lethal viruses or bacteria. Two self-closing doors serve as barriers for a lab of this degree, and access is strictly limited. Face/eye protection is used and respirators also may be required. All work should be completed in an application-specific BSC; the CDC recommends a Class II or Class III cabinet (see below for BSC specifics).

BSL-4 is the most rigorous biocontainment level. Very few BSL-4 labs exist around the world due to the highly dangerous potential for airborne infections (such as Ebola). If transmission occurs, the consequences can be fatal as there are few vaccines and ineffectual treatments in existence. The lab is either located in a separate building or contained within an isolation zone of an existing facility. All workers must wear a positive-pressure supplied air protective suit and tasks are performed in a Class III biological safety cabinet.

Terra Universal offers modular BSL-1 and BSL-2 cleanrooms, as well as BSCs appropriate for use in BSL 1, 2, and 3 environments. Contact one of our product specialists for information about your application-specific biological safety level.

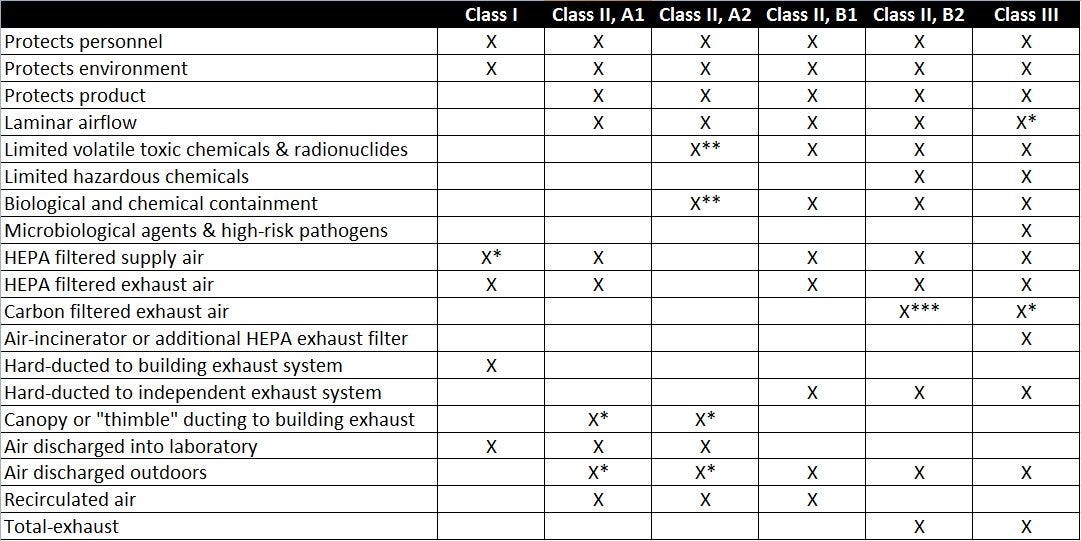

Biological Safety Cabinet Classifications

The CDC specifies three classes of BSCs. Class I provides the lowest amount of containment, while Class III is used for some of the most critical processes that require maximum protection. Below is a breakdown of specifications for each cabinet type.

*Optional

**A2-exhausted air only (not recirculated)

***Depending on application

Visit Biological Safety Cabinets for more specific product information.

As new diseases emerge, researchers must examine their cause. With advanced protective gear and strictly monitored work environments, scientists can more safely analyze and develop treatments. Biosafety levels bring us one step closer to the cure. For more information, visit our Biological Safety Levels page.