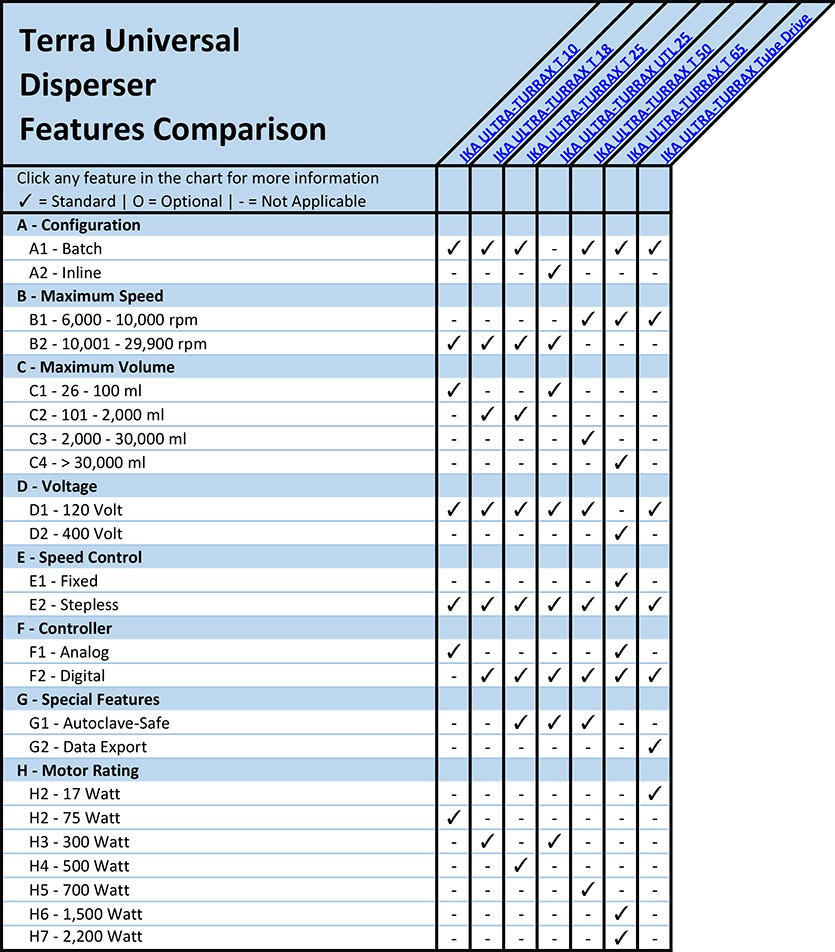

What is a Lab Disperser? How is it Different from a Homogenizer?

Laboratory dispersers, sometimes referred to as high-speed shearers or rotor-stator mixers, are a type of overhead stirrer designed to disperse, rather than mix, compounds. As opposed to homogenizers, which uniformly mix two or more miscible components, dispersers create a mixture of two or more immiscible components owing to liquid-liquid or solid-liquid phase separations. Popular dispersions include emulsions (liquid particles dispersed into another liquid) or grind dispersions (solid particles dispersed into a liquid).

What are Lab Dispersers Used For?

Laboratory dispersers are used in the biotechnology industry to form liquid biomolecular condensates, the food industry to produce vinaigrettes or homogenized milk, the pharmaceutical industry to create creams, ointments and salves, and the chemical industry to manufacture polymers, such as rubber or latex.

Dispersers are composed of a high-speed, spinning rotor connected to a stationary stator tube, regulated by an analog or digital controller. Interchangeable dispersing elements, such as cutting heads, propellers, dissolvers and saw tooth grinders, are installed onto the stator tube for different shearing applications. Although small-scale dispersers may be operated by hand, most models are mounted to a telescoping base stand for stability.

A - Lab Disperser Configuration

(back to chart)

A1 - Batch Lab Dispersers

Laboratory batch dispersers are designed for continuous mixing of bulk samples (up to 30 liters in volume), such as paint formulations, adhesives, ceramics, and oils. As sample viscosities change during the dispersion process, batch models are designed to maintain mixing speeds. Since batch processing may expose the emulsion to airborne contaminants, batch dispersers are not appropriate for sterile samples.

Shop Batch Lab Dispersers Online

A2 - Inline Lab Dispersers

Inline lab dispersers are designed for sterile, air-free, pressurized suspension, emulsification, and deagglomeration of inline fluid samples, such as pharmaceutical filling lines. Inline dispersers process smaller volumes than batch dispersers, but reach high speeds than most high-volume models.

B - Lab Disperser Maximum Speed

(back to chart)

Low-speed lab dispersers maintain mixing speeds of 6,000 to 10,000 rpm for applications such as premixes, balms, food gums and polymers. High-speed models boast mixing speeds up to 30,000 rpm for applications like tissue and cell homogenization.

Shop Lab Dispersers by Rotation Speed

C - Lab Disperser Maximum Volume

(back to chart)

Low-throughput batch dispersers and inline dispersers are designed to process samples between 26 ml and 2 liters in volume. High-throughput batch dispersers accommodate samples up to 50 liters in volume.

D - Lab Disperser Voltage

(back to chart)

120-volt connections are suitable for standard laboratory power outlets in the United States.

400-volt connections require less current (amperage) and smaller conductors than equipment designed to operate at 120-volt.

E - Speed Control

(back to chart)

E1: Stepless Lab Disperser

Stepless lab dispersers offer a full range of speed controls including small rpm increments for operations calling for specific mixing speeds.

E2: Fixed Lab Disperser

Fixed lab dispersers do not include speed range controls. These models are optimal for recurring mixing operations specifying one mixing speed.

F - Lab Disperser Controllers

(back to chart)

F1: Analog Lab Dispersers

Analog lab dispersers controllers include a speed dial and power switch. Economic alternative to digital models, these units do not include on-board software with timers and data export capabilities.

F2: Digital Lab Dispersers

Digital lab disperser controllers include a speed dial with LED readout of current mixing speed. Certain digital models, like IKA’s ULTRA-TURRAX T 65 disperser, include red emergency stop buttons for immediate shutdown.

G - Special Lab Disperser Features

(back to chart)

G1: Autoclave-Safe Lab Dispersers

Certain models, like IKA’s ULTRA-TURRAX T 25, are compatible with autoclave-safe dispersing elements for hands-free sterilization.

G2: Lab Dispersers with Data Export

IKA’s ULTRA-TURRAX Tube Drive system includes software to document performance and program saved methods as well as a USB interface to export data.

H - Lab Disperser Motor Rating

(back to chart)

Models designed for low-volume, low-viscosity stirring contain motors generating 17 – 300 Watts. High-volume, high-viscosity models contain motors generating 500 – 2,200 Watts.

High-Speed Disperser Manufacturers - Shop and Compare Lab Disperser Models

- IKA ULTRA T 10

- IKA ULTRA T 18

- IKA ULTRA T 25

- IKA ULTRA T 50

- IKA ULTRA T 65

- IKA ULTRA Tube Drive

- IKA ULTRA Tube Drive Workstation

- IKA ULTRA-TURRAX UTL 25

Laboratory-Equipment.com is a specialty division of Terra Universal. For nearly 40 years, Terra Universal has served semiconductor, aerospace, life science, pharmaceutical, biotechnology, and medical device markets. Customers appreciate a worldwide network of reps, factory-direct support, and ready-to-ship items available from Terra's manufacturing and warehouse facilities in Fullerton, California.

Shop online to compare pricing, features, and selection for a wide variety of lab equipment including dispersers, shakers, stirrers, and cold storage for applications including general laboratory, PCR, DNA/RNA techniques, ELISA, protein analysis, and cell culture.