Flammable gasses and vapors possess the potential to cause devastating damage to personnel, property and the environment. To minimize this danger, organizations including Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) develop standards, such as the National Electric Code (NEC), by which many industries operate. Explosions still occur, but damage can be minimized by using documented protocol for managing them. Companies involved with pharmaceutical development and manufacturing, fuel, chemical manufacturing, food manufacturing, aviation, and other high-risk applications have to abide by these established safety practices.

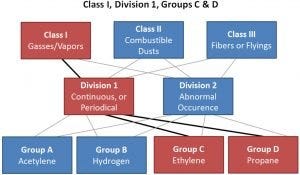

In each group of flammable-material type (gas/vapor, powder or fiber) the NEC categorizes risky environments based on this basic formula: material’s duration of use + its flammability potential = likelihood for fire. Equipment is designed to these specifications and appropriately labeled so companies know what to purchase based on their application’s classification. Terra Universal manufactures several explosion-proof cleanroom products, such as the Explosion-Proof Modular Softwall Cleanroom, built for Class I, Division 1, Groups C and D activities.

NEC Class relationships

*Groups E and F are not defined in the diagram above; they are metal, carbon and plastic dusts.

The modular cleanroom starts with a sturdy powder-coated steel frame, fortified with cross-bracing to support heavy ceiling components. The room is free-standing; optional casters turn the room into a mobile unit, easily rolled to alternate locations. A steel ceiling grid provides support for lights, filters and power. Empty grid bays hold ceiling panels made of non-conductive gypsum, a common mineral used in fire-resistant materials.

Fan/Filter Unit

Explosion-proof fan/filter unit, encased in cast-iron housing.

The heart-and-soul of any cleanroom is the filter module. This UL-certified explosion-proof unit has a non-sparking, fan-cooled motor mounted in cast-iron housing. It is designed for continuous operation in Class I or Class II, Division 1 cleanrooms or hoods. Wiring is packed inside steel conduit filled with non-conducting, non-flammable cement to keep wiring rigid and neutralize static discharges.

FFUs come with a pre-filter and either a HEPA or ULPA filter to remove ³99.99% of particles as small as 0.3 um (HEPA) or 0.12 um (ULPA) from laminar-flow air being released into the controlled enclosure. At the average air speed of about 100 feet/minute, these FFUs have a noise level of 49 decibels and keep your room rating at ISO 5. Internal baffles and a diffuser panel make laminar airflow uniform and consistent, simplifying your ISO-compliance efforts.

Electrical System

Each Terra cleanroom has a dedicated, UL-certified, stand-alone power distribution module (PDM). It aggregates all powered modules into a central location that integrates with a single electrical source. In the explosion-proof cleanroom, the PDM is encased in water-tight, corrosion-resistant aluminum. Cement-packed conduit connects each powered module to the central PDM. Class I/Division 1-compliant control switches are conveniently located in one corner of the room, giving workers the ability to manually control lights and FFUs.

Filled conduit encasing electrical wiring

Each section of conduit array is labeled for easy installation and maintenance. The sections have quick-disconnect couplings at the terminal ends, allowing assembly that does not compromise the electrical system or carefully packed wiring; no tape or other seals are necessary. Couplings adhere to Class I/Division 1 requirements by creating seals that resist moisture, vapor and dust.

Potted fittings are factory-installed in the conduit lines. They are safety precautions that serve to separate the modules’ electrical lines, preventing fire spread in the event of an explosion. Like conduit, fittings are filled with non-conducting cement.

Lighting

Light your workspace, and be eco-friendly at the same time with the long-lasting, low-amp explosion-proof LED light. Each energy-efficient light module provides 3,600 lumens and is rated for over 100,000 hours of illumination. The low-profile module is UL-listed for use in Class I/Division 1 and 2, Groups C and D working areas. LED lamps produce less heat than standard bulbs, so are a good choice for high-risk facilities.

Softwall Curtains & Strips

Static charges are dangerous when working with flammable materials. With explosive gasses and vapors in the air (mixing with oxygen), the addition of an electric spark can cause an explosion. To mitigate this problem, Terra’s explosion-proof cleanroom has soft walls made of transparent 60-mil static-dissipative PVC curtains and strips. Curtains, used for “walls” are four-feet wide and overlap by six inches; strips, used for the “door” are 8 inches wide and overlap by two inches.

Static inhibitors are ingrained into the SDPVC material, preventing the build-up of electro-static discharge, and the attraction of particles. ASTM testing shows that SDPVC softwall material maintains a surface-resistance of 1.8 x 107 ohms/sq.

Other Explosion-Proof Equipment

Explosion-proof hood

In addition to this softwall cleanroom, Terra has other explosion-proof, cleanroom-compatible equipment available:

- The fan/filter unit and LED lighting module described above can be mounted in other cleanrooms, gloveboxes or hood enclosures

- Other lighting options include vapor-sealed fluorescent lights (certified for Class I, Division 2, Groups A – D) and a compact incandescent illuminator tested for Class I, Division 1 and 2 (Groups C and D), Class II, Division 1 and 2 (Groups E and F*) and Class III, Division 1 and 2 (all Groups)

- Explosion-Proof Hood, for Class I and II, Division 1 locations, is a turnkey vertical or horizontal laminar-flow work station that features the explosion-proof fan/filter unit, LED light and filled conduit. The hood frame is either stainless steel or powder-coated steel, using SDPVC panels and sash

Click for more information about Terra’s Explosion-Proof Softwall Cleanroom.