Terra Pass Through Design and Performance Features: Short Descriptions

Passthrough chambers are used in cleanrooms and controlled environments across countless industries and applications. Passthrough cabinets have many benefits. Aside from reducing foot traffic in controlled areas, they also help meet special cleanliness, safety, and security requirements in different industries. For instance, pharmaceutical cleanrooms require compliance with USP <797> and USP <800> guidelines for compounding sterile medications and hazardous drugs. Other cleanrooms and labs handling biohazards require similar strict sterilization protocols, plus autoclave-safe designs. Facilities manufacturing sensitive electronics may not require frequent sterilization, but may have other special requirements for ESD-safety and controlled air spaces to minimize particle counts inside the cleanroom.

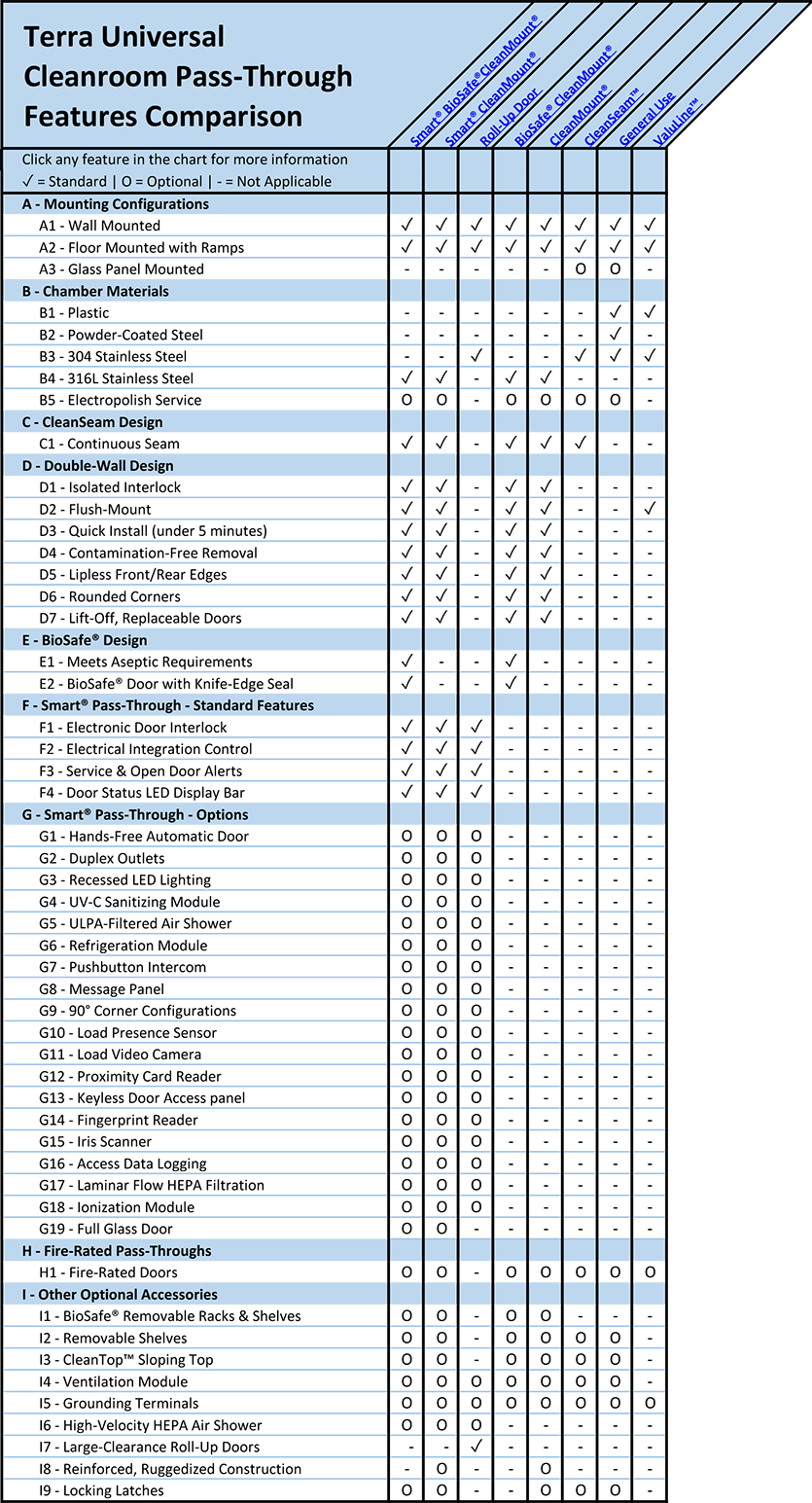

Terra Universal manufactures and stocks cleanroom passthrough designs for every application. The different designs include combinations of unique features to help meet application specific cGMP standards and protocols for cleanliness, safety, and security.

Below is a comparison chart of Terra’s cleanroom passthrough designs, along with a complete break-down of the features and benefits, to help you compare and choose the best design for your application. You can click on any row of the chart to take you to a detailed summary of the specific feature. Call or chat with a live specialist to ask any questions or request a free quote.

Application Notes:

- Smart® CleanMount® pass-through chambers with electronic controls and monitoring capabilities are designed for sterile, regulated environments with critical cleanliness applications.

- CleanMount® pass-through chambers seamlessly install within minutes, and mount flush to cleanroom walls to support critical cleanliness applications with strict disinfection protocols.

- BioSafe® CleanMount® pass-through chambers, with autoclave-safe doors, are designed for critical biological applications with strict sterilization protocols.

- CleanSeam™ pass-through chambers, designed without crevices, are suitable for pharmaceutical applications requiring controlled air spaces and moderate sterilization protocols.

- General-Use cleanroom pass-throughs are suitable for non-sterile cleanrooms or educational labs that require controlled air spaces.

- ValuLine™ pass-through chambers are suitable for non-sterile applications that do not require controlled air spaces.

- Roll-up door cleanroom pass-throughs are designed for transferring tall carts or large equipment into a cleanroom on a regular basis.

A - Mounting Configurations:

(back to chart)

A1 - Wall Mounted: Terra offers flush-mount and center-mount options. Terra’s CleanMount® system affixes flush against the cleanroom wall to simplify disinfection and prevent particle accumulation.

A2 - Floor Mounted With Ramp: Cleanroom cart pass throughs with integral ramps support transfer of heavy equipment or sample racks into critical spaces.

A3 - Glass Panel Mounted: Stainless steel pass throughs smaller than 2 cubic feet may be mounted in tempered glass panels without support frames, saving facilities on additional hardware and cleaning costs.

B - Chamber Materials:

(back to chart)

B1 - Plastic: Terra manufactures and stocks pass through chambers made of economical acrylic, ESD-safe static-dissipative PVC, and chemical-resistant polypropylene.

B2 - Powder-Coated Steel: More economical than stainless steel, durable and rigid powder-coated steel is more resistant to chemical- or moisture-based corrosion than plastic designs.

B3 - 304 Stainless Steel: 304-grade stainless steel resists most harsh chemicals and alcohol-based cleaning agents, and won’t produce contaminants during sterilization.

B4 - 316 Stainless Steel: 316-grade stainless steel contains more nickel and molybdenum than 304-grade stainless steel, enhancing its resistance to corrosion in wet environments, degradation from bleach-based disinfectants, and high-temperature sanitation, like autoclaving.

B5 - Electropolished Service: Electrochemical polishing improves the surface finish of the stainless steel, and supports easy sterilization to reduce micro-cavities where microbes colonize.

C - CleanSeam Design:

(back to chart)

C1 - Continuous Seam: Terra’s CleanSeam™ pass through chambers feature fully-welded chambers with smooth, continuous seam welds for a seamless interior that is easy to disinfect. The internal chamber is free of crevices or cracks where contaminants can collect.

D - Double-Wall Design:

(back to chart)

Equipping a pass through cabinet with external components - such as door sensors, lighting and filtration – can be a challenge. Cleaning procedures dictate that pass through chambers should be seamless, crevice-free and easy to wipe down. Installing external components on the chamber will make the cleaning process more difficult and restrict the space available for sample transfer.

Terra has solved this issue with CleanMount® double-walled pass through chambers. All external components are enclosed within the space between the internal and external walls, so the integrity of the internal chamber is not jeopardized and the pass through cleanliness rating is not sacrificed.

Double-wall construction has additional benefits: the unit is more rigid and more stable within the wall, the doors achieve a tighter seal and more precise alignment with the chamber, and the interlocking mechanism operates flawlessly.

CleanMount® double-walled systems provide one additional benefit: they are pre-compatible with a wide array of Smart® electronic add-on features, such as UV lighting, valuline filtration, refrigeration modules and load presence sensors. As the bulk of the additional cost for these add-on features are built into the double-wall design, Terra’s pass throughs can be fully equipped with Smart® electronic controls for a negligible price. While the cost to add these features is low, the benefits are enormous - your pass through chamber is instantly transformed into more than a sample transfer system: a germicidal system, a method for employee communication, a data logger, or a security device.

D1 - Isolated Interlock: Effectively cleaning an internal chamber with an exposed interlock is a huge challenge. Terra offers a fully isolated automatic interlock, installed between the interior and exterior wall panels of the cleanroom transfer hatch.

D2 - Flush-Mount: Terra’s CleanMount® system mounts flush against the cleanroom wall to minimize particle accumulation and simplify cleaning.

D3 - Quick Install: The whole process of installing a pass-through was very messy, until Terra developed the CleanMount® pass-through. The CleanMount® fastening system installs directly into a clean, finished opening in the wall (not a dirty, rough cut-out) without any drilling or screwing into the surrounding wall that can contaminate and delay cleanroom operations. The innovative design firmly clamps to a variety of wall thicknesses without penetrating or damaging the finished surrounding wall. After the wall is fully prepared by your contractor, Terra’s CleanMount® pass through chamber can be installed seamlessly, within 5 minutes. Terra’s video tutorial will guide your contractor through the process to ensure the pass through is correctly installed.

D4 - Contamination-Free Removal: CleanMount® pass throughs also drastically simplify maintenance to minimize downtime of critical cleanroom operations. The units can be removed and reinstalled seamlessly, within minutes, by any member of your organization. If your pass through chamber needs servicing, Terra’s CleanMount® chamber easily slides out of the wall without creating scratches or abrasions that can leave debris and particle contamination in the cleanroom.

D5 - Lipless Front/Rear Edges: The edges of a pass through chamber are prone to snag garments and collect contaminants. Terra’s CleanMount® and BioSafe® design includes lipless front and rear edges for easy sterilization.

D6 - Rounded Corners: The corners inside a pass through chamber are a common spot for contaminates to collect or microbes to colonize. Terra’s CleanMount® and BioSafe® pass throughs feature fully rounded (radius) corners for easy disinfection.

D7 - Lift-Off Replaceable Doors: Effectively disinfecting pass-through doors can be a challenge. Both Terra’s CleanMount® and BioSafe® pass-through chambers include removable doors. BioSafe® passthroughs feature autoclave-safe doors with blue elastomeric door seals.

E - BioSafe Design:

(back to chart)

E1 - Meets Aseptic Requirements: Terra’s pass through chambers are UL-rated, CE-marked and leak-tested. Specialty models meet USP <797> and <800> requirements, cGMP standards, UL-B fire ratings, and BSL 1 and 2 criteria. If you’re installing a pass through into a regulated space, talk to your Terra product specialist to find a model to fit your application.

E2 - BioSeal Door with Knife Edge Seal: For many applications, maintaining positive or negative pressure inside of a cleanroom is critical, whether the environment is sensitive to particles, microbial growth, moisture or static build-up. Your cleanroom’s pressure rating can be compromised by any personnel entrance or exit, including your pass through chamber. Terra’s pass through chambers will support the integrity of your cleanroom, allowing it to maintain your desired cleanliness levels and specifications. Terra’s BioSeal™ doors with elastomeric gaskets are pressure-rated, autoclave-safe and compatible with critical, regulated environments.

F - Smart Pass-Through Design – Standard Features:

(back to chart)

F1 - Electronic Door Interlock: Pass through chambers must be designed to prevent both doors from opening at the same time, causing cross contamination between two sterile spaces and a loss of your cleanroom’s pressure rating. A critical component in the pass through design, the interlocking mechanism, prevents this unwanted occurrence. The interlock can be mechanical, utilizing a hook and latch system, or electrical, using an e-strike. Mechanical interlocks come in two flavors: manual or automatic. For mechanical interlocks, Terra only offers automatic systems, as manual systems must be engaged by the operator, severely reducing transfer efficiency. In certain applications, Terra pass through chambers are opened every five seconds for the entirety of a work shift. This level of access frequency would not be possible with a manual, mechanical interlock. Electrical interlocks are often installed on passthrough chambers with automatic, hands-free doors or systems equipped with access controls, occupancy sensors, building management integration or event logs. Terra’s Smart® pass-through chambers can be equipped with these capabilities and more, including refrigeration modules, intercoms, UV germicidal lighting and HEPA filtration.

F2 - Electrical Integration/Control: When first introduced to the market, the pass through chamber had one specific job: to act as the gatekeeper for sample transfer into and out of the cleanroom, thereby reducing personnel traffic. As the pass through has become more integral to the operations within a cleanroom, the potential jobs it can perform and problems it can solve have increased. Terra has changed the definition of the pass through chamber by offering a menu of standard, add-on features that expand the role of the pass through chamber within a cleanroom. Beyond sample transfer, a pass through can now disinfect products, allow employees in separate areas to communicate, log environmental conditions, track personnel or packages, and add layers of security to your facility.

F3 - Service & Open Door Alerts: In regulated environments, like FDA or cGMP facilities, event logs that track employee movement, environmental conditions, equipment status, and service alerts are a requirement. Terra’s Smart® Pass Through captures these data and communicates with your building management system or LIMS software to export the data at stated intervals.

F4 - Door Status LED Display Bar: The interlocking mechanism is the lifeblood of the pass through chamber; its integrity dictates the life of the unit. If the interlock doesn’t function effectively, your facility may experience sample cross contamination, product failures, or employee safety issues. The interlock, and by proxy, the pass through doors must be operated correctly; misuse can shorten the lifespan of your pass through and decrease its effectiveness. To reduce interlock abuse, Terra has introduced several solutions, such as buzzers and color-coded warning signals. Terra’s Smart® LED Door Status Bar displays a red light when the opposite door is open, informing the operator to wait before attempting to open the door, and a green light when the opposite door is shut, informing the operator to proceed in opening the door. Without a status bar, interlock abuse is common: an operator will attempt to open the door, not knowing that the opposite door is open; when their door doesn’t open, the operator will use excessive force to pry the door open, causing damage to the door seal and the interlock. These signals act as the traffic lights for Terra’s Smart® pass through chambers, ensuring interlock abuse is prevented. If traffic lights didn’t exist on roadways, would car accidents be blamed on automotive manufacturers? In this same vein, Terra has taken the extra step in supporting pass through care, so our customers can reap the full benefits of our system for many years.

G - Smart Pass-Through Options:

(back to chart)

G1 - Hands-Free Automatic Door: In the semiconductor industry, the highest level of contamination control is achieved by totally eliminating the presence of humans in the critical manufacturing areas through full robotic automation and closed-loop enclosures. Terra Universal has developed and offered solutions for the semiconductor industry since its inception in 1976. We understand the benefits that reducing foot traffic will have on a company’s operations, processes and products. Terra’s Smart® pass through chambers can be equipped with automatic doors and electronic controllers that support integration with fully automated systems.

G3 - Recessed LED Lighting: LED lighting illuminates the internal chamber and mounts flush into the ceiling for easy sterilization. The light automatically activates when either door opens, supporting hands-free operation of the pass through chamber.

G4 - UV-C Sanitizing Module: Germicidal UV-C light, emitted at 254 nanometers, denatures microbial DNA after short, intense exposure. UV-C lighting will ensure your pass through box is fully sterilized and does not impact the bio-burden of your cleanroom.

G5 - ULPA/HEPA-Filtered Air Shower: Recirculating filtered pass throughs use a closed loop system to continuously recirculate air in the chamber through built-in HEPA or ULPA filters. These clean air pass thrus are self-contained and do not require any ventilation or exhaust ducting. They run continuously to reduce particle concentration within the chamber. This design is commonly used because the closed-loop system does not impact adjacent room pressure balances when operating.

With heavily mandated cleanliness requirements associated with USP 797 and USP 800 cleanrooms, a pharmacy pass thru is a vital point for sterile pharmaceutical compounding. Terra’s HEPA filtered pass through and Smart® HEPA filtered pass thru use recirculating ventilation to meet and exceed USP 797 and USP 800 guidelines.

Comprehensively wiping down a cart filled with patient samples or supplies can be time consuming. Terra’s high velocity air shower pass through is designed with high-pressure nozzles that wash the cart from every side with ULPA-filtered air. After a 30-second, hands-free wash cycle; your cart will be clean, particle-free and contamination-free. As a secondary disinfection mechanism, equip your cart with a germicidal, UV-C light to prevent microbial growth.

G6 - Refrigeration Module: For temperature sensitive samples or equipment, Terra’s Smart® pass throughs may be equipped with a refrigeration module that maintains a 4°C set point within the internal chamber. Terra’s high-security, refrigerated pass through chambers are utilized for overnight storage of patient samples.

G7 - Pushbutton Intercom: Built-in intercom system allows operators to easily communicate between rooms. Without intercoms, operators are prone to opening both pass through doors, by bypassing the interlock, to communicate, thus breaking the cleanroom seal and exposing sterile areas to cross contamination.

G8 - LCD Message Panel: LCD panels are designed for regulated environments, like FDA, cGMP, GLP or USP <797> facilities. They display critical environmental information related to the interior chamber conditions, such as temperature and relative humidity.

G9 - 90° Corner Configurations: Terra has 45 years of experience in customized equipment. Smart® pass-throughs with custom door configurations can be designed per-project to install in corner walls with multiple doors: 2 doors (L-shape), 3 doors (T-shape), or 4 doors (X-shape).

G10 - Load Presence Sensor: Infrared beams detect objects placed within the internal transfer chamber and communicate date to an audible remote alarm located up to 200 feet away from the pass through. System is ideal for highly-regulated facilities maintaining cGMP compliance or systems installed onto the external wall of a building for package delivery.

G11 - Video Camera: An interior HD video camera records continuously or upon door opening. The camera can also be adjusted to monitor spaces external to the pass through chamber.

G12 - Proximity Card Reader: Card readers with system lockout and keypad for two-factor authentication are ideal designed for pharmacies dispensing controlled substances.

G13 - Keyless Door Access Panel: Keypad readers for high-security areas prevent unauthorized access to the pass through chamber.

G14 - Fingerprint Reader: Biometric fingerprint scanners include proximity card reader for two-factor authentication.

G15 - Iris Scanner: A fully automated iris scanner provides secure, hands-free access and includes data logging plus a secondary keycard reader.

G16 - Access Data Logging: This software logs environmental conditions and exports the data to a local server or building management system.

G17 - Laminar Flow HEPA Filtration: Terra’s Smart® pass through cabinets may be equipped with a HEPA-filtered blower module, installed above the unit, that washes the internal chamber with uniform, unidirectional, micro-filtered air.

G18 - Ionization Module: Ion bars emit a static neutralizing stream of cations and anions to prevent ESD discharge. They are ideal for protecting static-sensitive medical devices and microelectronics.

H - Fire-Rates Pass-Throughs:

(back to chart)

H1 - Fire-Rated Doors: If you are installing a pass through chamber in a fire-rated space, the pass through must carry the same fire-rating as the wall in which it is installed. Terra’s fire-rated pass through chambers carry the UL-B label for 90-minute fire exposure, suitable for installation in areas with 2-hour wall ratings. Available in 11 different sizes to fit your sample transfer needs, Terra offers fire-rated units that are pre-tested, crated and in-stock for immediate shipment.

I - Other Optional Accessories:

(back to chart)

I1 & I2 - BioSafe Removable Racks and Shelves: Stainless steel racks and shelves can be removed for disinfection or replaced as user requirements change.

I3 - CleanTop Sloping Top: For non-flush mount pass through systems, Terra’s CleanTop™ sloping top provides a smooth, easy to disinfect surface between the pass through door and the wall.

I4 - Ventilation Module: A cleanroom pass thru chamber with exhausted ventilation (also known as a sink airlock) provides a single pass (open loop) supply of exhausted air. This extraction system creates negative pressure to prevent particles from escaping the chamber from either door. This design can be used for applications where hazardous materials or particulates must be contained and kept from passing through either side of the chamber. Ventilation units can also be used to duct fumes that might be present in a specimen, allowing the cleanroom pass thru box to act as a drying system. Specify a flange adapter to allow connection from the pass thru chamber to an in-house ventilation system. Exhaust air speed sensors can also be configured for added safety to alarm in the event air speed falls below a specified set point.

I5 - Grounding Terminals: For static-sensitive material, Terra’s cleanroom pass through box can be equipped with grounding terminals for an ESD-safe internal chamber.

I6 - High-Velocity side & Top HEPA Air Shower: Installed on floor mounted pass throughs, the air shower directs HEPA-filtered air through high-velocity nozzles installed on the ceiling and walls of the internal chamber to wash carts free of dust and contaminants.

I7 - Large-Clearance Roll-Up Doors: Terra’s roll-up door pass throughs are designed for consistent, high-throughput transfer of large, bulky equipment into and out of the cleanroom. Roll-up pass thru designs include safety pressure sensors, automatic interlocks, touch panel interfaces, and laser door positioning sensors.

I8 - Reinforced, Ruggedized Contruction: Rugged pass through transfer hatches featuring double-wall construction and heavy-duty self-closing doors are designed for high-throughput, high-security areas such as correctional facilities.

I9 - Locking Latches: For secure areas housing controlled substances or high-value products, Terra offers a variety of locking door latches and access controls for pass thru cabinets.