Why a Nitrogen Generator Belongs in Your Lab

Forget about renting nitrogen tanks — laboratory applications aren’t on the same level as buying helium for a kid’s birthday balloons. Critical operations can’t wait for resupply. What happens when production stops because the gas supply has depleted, or when valuable experiments or products are ruined because of moisture exposure? As far as the old-fashioned nitrogen delivery via tank and truck, why wait to have crucial laboratory supplies left on the cleanroom stoop like old milk bottles? How much time should personnel have to spend refilling each tank? And where in the space-starved facility should the bulky supplies wait for use?Terra’s portable Nitrogen generator solves this problem by producing up to 99.9% pure medical grade nitrogen gas inside your lab. These units are ideal for supplying a continuous flow of Nitrogen gas to desiccator cabinets, gloveboxes, vacuum chambers, and more!

What are the advantages of a Nitrogen Generator?

What could replace the inefficient system of pre-filled Nitrogen cylinders? Something with a reliable, steady stream of clean, dry nitrogen, one that doesn’t take all the effort and planning and time. Enter: the nitrogen generator. What exactly makes it so superior?

- Low long-term operating cost: cutting out the repeating operating costs of tank rental, delivery, and administration adds up to big long term savings. These savings multiply for more intensive N2 requirements.

- No supply constraints: A membrane Nitrogen generator only requires a line of compressed uses the ambient air to complete its process supply a continuous flow of pure Nitrogen gas. It does not need to be plugged into an electric power supply.

- Adjustable purity and flow rate: Control the flow rate and purity of the nitrogen rests to fit your specific application needs.

- Compact and portable: A nitrogen generator has a small, unchanging footprint—its slim tower design takes up less floor space than a set of canisters.

- Low maintenance: It takes no reloading or moving around—it’s a one-and-done kind of device until it needs a filter change in about 5-10 years.

- Efficient: Every drop of the nitrogen it produces can be used—no more almost-empty tanks.

Cost Savings with an On Site Nitrogen Generator

The greatest cost of nitrogen generation after the up-front purchase of the generator itself is the continual energy of running the air compressor — though some facilities already run compressed air to operate other machinery. But even if they don’t, and purchasing a compressor seems daunting, rest assured that producing in-house nitrogen still has the best financial benefit. Over time the cost of the equipment becomes negligible compared to the never-ending cycle of tank deliveries, and if the lure of on-site nitrogen generation isn’t enough already, contact our representatives—they can help calculate the long-term cost to prove the juice is worth the squeeze.

What are the disadvantages of pre-filled Nitrogen cylinders?

- High long-term operating cost: Nitrogen cylinders require rental, delivery, and admin fees. These costs can be significant over a long term time horizon.

- Supply constraints: The nitrogen supply can run out during sensitive operations if there’s a leaky tank or a miscalculation on required canisters.

- Logistics and lag time: It takes purchasing, delivery, storage, and changing canisters on an infinite cycle to use this method. The lab has to wait for supplies before it can run tests or perform necessary operations.

- Bulky storage and safety requirements: Bulky canisters take loads of storage space in a cleanroom, where every inch of space is already economized. They require special, organized safe storage protocol

- Difficult to move: They’re heavy, easy to drop (not to mention loud), and generally unpleasant to have to change, especially in the middle of a critical procedure.

- Inefficient: Nitrogen cylinder services offer a fixed purity and amount per canister. If your service is supplying 99% Nitrogen gas for an application that only requires 95% purity, that may be money down the drain. Furthermore, that last bit of nitrogen always stays in the canister—even though it’s paid for.

How Does a Nitrogen Generator Work?

How a Membrane Nitrogen Generator Works

This system forces air through semi-permeable membrane fibers, which separates the gases and compounds. Ambient air consists of approximately 78% nitrogen and 21% oxygen, along with a spattering of other elements. The process of creating purified nitrogen gas starts with an air compressor, which sends pressurized, ambient air through the nitrogen generator’s set of coalescing pre-filters to remove particulates, oil and moisture. The pre-filters extend the life of the main filter: the nitrogen membrane module.

Because nitrogen is a “slower” gas than oxygen (and carbon dioxide and water), it will not diffuse through the membrane in the time of exposure; oxygen’s greater solubility makes it more likely to permeate the membrane. The other air leaves the filter, and the nitrogen continues to a separate container. No chemicals, no hassle — just an occasional filter change and a simple system that functions based on the physical properties of ambient air, which creates up to 99.9% pure nitrogen — perfect for the majority of laboratory uses

For even purer nitrogen, leave the pressure as-is, but slow the process down to allow time for more unwanted gases to pass through the filter.

How a Pressure Swing Adsorption (PSA) Nitrogen Generator Works

Another type of nitrogen filtration, typically used in ultra-pure nitrogen applications, is pressure swing adsorption (PSA). The PSA nitrogen generator system uses multiple cylinders that take turns bearing the pressure — the compressed air blows into one side, into a filter called a Carbon Molecular Sieve (CMS) that adsorbs almost all elements except N2, then switches to use the other side while the first one is blown clean with pure nitrogen to ready it for use to isolate more nitrogen. It seems like a far more convoluted method than the membrane — and it absolutely is — but if the task requires 99.999% pure nitrogen, that’s the way to go. The space required for PSA takes more than the nitrogen membrane module, so smaller cleanrooms and laboratories might favor the more economical method.

Airflow Rates vs. Purity: The Tricky Part Made Simple

Learning how to control the generator system could give a potential buyer pause — nitrogen canisters have direct purity and easily adjusted airflow, which might seem convenient in the face of daunting calculations for generating pressure, airflow and purity. But the system requires the simple turn of a knob to operate, and the examples below clarify it.

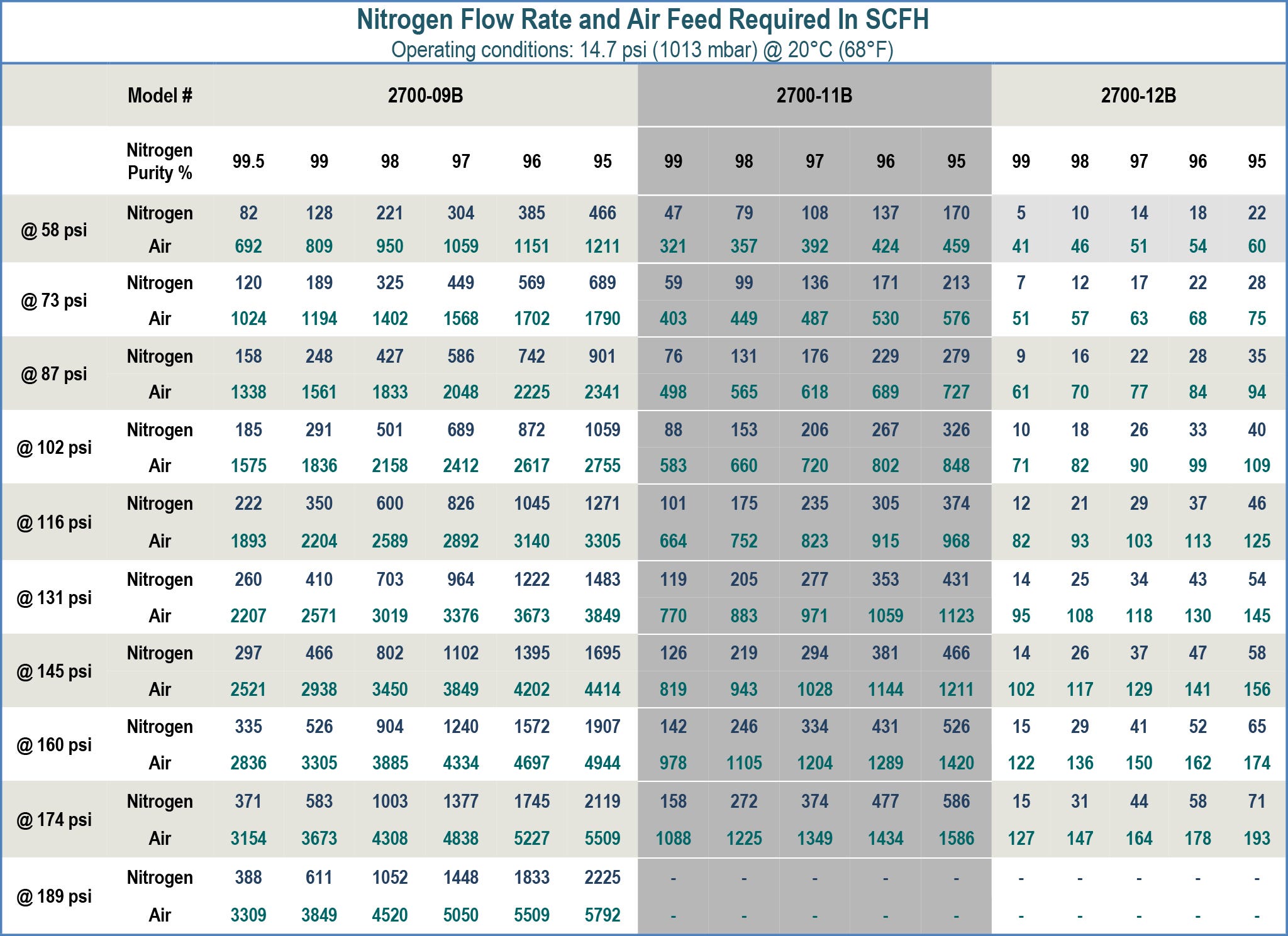

Terra offers three sizes/capacities of compact Nitrogen generator cabinets. A small Nitrogen generator cabinet is ideal for the smallest of desiccator cabinets or other enclosures. Larger sizes offer increased flow rate depending on your needs. The charts and diagram below show the operation of Terra’s N2 generator cabinets given 200 PSI and 113°F. The flowrate ranges represent different purity levels; the higher the purity, the lower the flow rate.

If you want a certain purity of nitrogen, you have to adjust the rate of air flowing out of the nitrogen membrane module. The lower the outflow rate, the more time the module has to comb through the air and separate nitrogen from the other gases.

Nitrogen Flow Rate & Feed-air consumption in SCFH

Flow vs. Purity @ 50° C (122ºF)

(Based on 77° ambient)

High Capacity Nitrogen Generator

For a higher volume of nitrogen or a complete turnkey solution, choose Terra’s High Capacity membrane Nitrogen generator. With a 200-gallon compressed-air storage tank and a 60-gallon nitrogen holding tank, this industrial Nitrogen generator can provide nitrogen as needed without the requirement for continuous operation. When continuous operation is required, the 50 HP rotary screw compressor provides up to 157 ACFM to the generator.

This model is designed for installations that either lack a sufficient supply of compressed air on-site, or where using the built-in compressor would be more efficient than running high-pressure lines to the system.

The solution to clunky tanks, wasted time and late deliveries lies in the air around you. Forego the stress of an antiquated system, and tap into the biggest supply of nitrogen available with Terra’s Nitrogen gas generator.