Vacuum Overview

“Vacuum” means the complete absence of matter. In order to create vacuum conditions, pressure within a given space must be lower than the surrounding environment. The quality of the vacuum is dependent upon several factors, including the number of particles within a given space. The inertia of moving particles exerts pressure, so fewer particles means lower pressure. Scientists have given up on the idea that a perfect vacuum is even possible; space is the most ideal vacuum we know of, but hydrogen atoms, energy waves and other moving particles are still present.

Vacuum Chambers

Imperfect as they are, we create vacuums for various applications and processes: sealed chambers that help researchers and manufacturers with tasks including leak testing, stress testing, degassing, drying, distillation, permeability testing, coating, specific gravity determination, atmospheric simulations and storage.

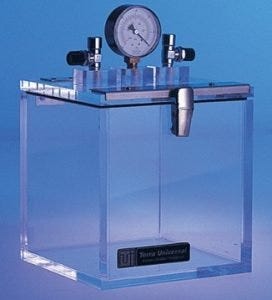

Acrylic vacuum chamber with valves and pressure gauge

Chambers are made of durable material that can withstand the pressure differential, such as steel, aluminum, glass and acrylic. The walls are generally thick to prevent physical failure resulting from the force of outside pressure.

Valves & Gauges

Vacuum chambers come equipped with valves and gauges. Metering valves enable the connection to vacuum pumps, for removal of internal particle- and moisture-laden air. These valves also provide an inlet for process gas, such as nitrogen, for purging or drying purposes. Bleed, or safety, valves protect both the chamber and the samples from damage, in case pressure gets too low; outside air is allowed in, increasing pressure to the desired level. Gauges are used to measure and display the vacuum chamber pressure.

In many labs, controlling the vacuum chamber’s target pressure is a manual or semi-automated task, using the valves and gauges. Terra Universal makes a Vacuum Control Module that features a digital control panel for setting the target vacuum level. An electric pump attached to the chamber operates continuously to maintain the programmed pressure. An optional solenoid valve helps increase the efficiency and accuracy when installed between the chamber and the pump; it switches the pumping action on or off as needed, according to signals from the control module.

eVAC Digital Vacuum Controller

Automated Vacuum Control

Terra’s newer vacuum control solution is their eVAC™ Digital Vacuum Controller. It interfaces with an electric pump, and features a digital control panel, much like the Vacuum Control Module. However, an electric bleed valve is included in the system, which automatically releases room air into the chamber when triggered by a sensor. So, while the Vacuum Control Module allows pressure to be electronically increased, the eVac supports automatic increases and decreases in pressure. This flexibility results in faster, hands-off set-point response time, allowing more tests with varying atmospheric conditions. Choose your pressure goal, push a button, and walk away!

eVAC comes with a thermocouple gauge, which measures temperature fluctuations of the internal vacuum chamber. As pressure rises, so does the temperature. Fluctuations prompt the sensor to initiate pumping activity, controlled by a solenoid valve, or introduction of outside air, controlled by the bleed valve. The thermocouple gauge, with response time of less than three seconds, measures pressure in a range of 1 milliTorr to 760 Torr. Working in tandem, these components automatically maintain the chamber’s programmed pressure level, without intervention or oversight by lab personnel.

Acrylic vacuum chamber

All lab processes require time-consuming documentation, but the eVAC relieves some of the burden with its unique software package. Data input and output are recorded in a user-friendly applet, with the option to export to .csv for future analysis or reporting in spreadsheets. There’s even a graph for real-time visualization of chamber tests-in-progress, showing user setting manipulations. This is a good way to check for errors and make fast adjustments.

Link the controller to a computer using Ethernet cable or a standard RS232 pin connection. eVACs can be assigned unique IP addresses, so labs with multiple vacuum test chambers can use a single PC to manage all controllers.

Final Thoughts

Complete more tasks in less time using smart controllers such as Terra’s eVAC Digital Vacuum Controller. Fluctuations in vacuum levels that may otherwise render an experiment or manufacturing process invalid can be avoided with a reliable, automated system. Get peace-of-mind when storing sensitive materials, or working with limited samples.

Click here for more information about Terra’s eVAC Digital Vacuum Controller.