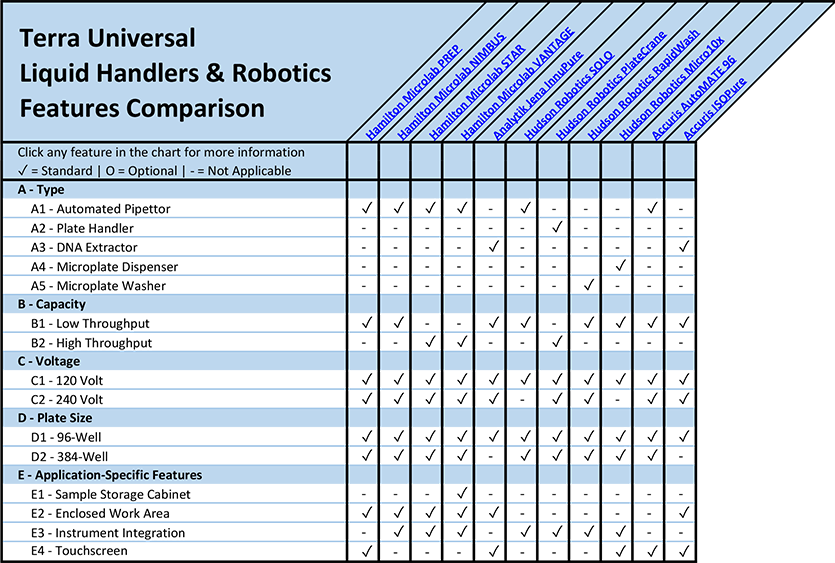

Title: Liquid Handers and Automated Microplate Systems Comparison

Laboratory liquid handlers are a class of automated instruments used to dispense, transfer, dilute, or mix samples and reagents. Liquid handlers accurately handle small sample volumes, ranging from microliters to milliliters, and perform a variety of operations, including pipetting, mixing, and serial dilution.

Automated liquid handlers offer several benefits when compared with manual experimental prep.

- Accuracy: A liquid handler can accurately dispense the exact volume of sample or reagent, with minimal errors or variations.

- Precision: The precision of a liquid handler is much higher than manual pipetting, allowing for reliable and reproducible experimental data.

- Efficiency: A robotic liquid handler can process large volumes of samples quickly and efficiently, freeing up valuable time for researchers.

- Flexibility: A liquid handler can accurately dispense a wide variety of liquids, from viscous solutions, such as glycerol, to low-volume samples.

- Time-Saving: A laboratory liquid handler can automate repetitive tasks, freeing up time for researchers to focus on concurrent work.

- Cost-Effective: By reducing human error and minimizing the need for manual pipetting, liquid handlers can cut down on wasted consumables and reagents, improving the overall efficiency of the lab.

- Quality Control: As liquid handlers perform reaction prep in an enclosed, operator-free environment, instances of sample cross-contamination are rare.

Liquid handlers are commonly used in high-throughput screening (HTS), drug discovery, and genomics research to speed up and optimize experimental workflows. Other common robotic laboratory instruments include plate washers, reagent dispensers, plate handlers, and nucleic acid extraction systems.

A - Liquid Handler Types and Differences

(back to chart)

A1 - Automated Pipettors for Testing, Development, and Research

The largest class of liquid handling instruments is composed of automated pipettors – robotic systems designed to dispense precise sample or reagent volumes. Automated pipettors are equipped with a motorized mechanism, called the pipetting head, that pulls the liquid (sample or reagent) into a disposable pipette tip, and then dispenses the solution accurately and precisely into a targeted vessel, such as a microplate, micro-tube, or liquid basin. Automated pipettors are commonly used in clinical diagnostic testing, drug development, and molecular biology research.

A2 - Plate Handler Lab Equipment Features

A laboratory microplate handler (also referred to as a microplate robot or plate mover), is an automated device designed to transfer microplates between workstations and lab instruments, such as centrifuges, plate readers, microplate shakers, plate sealers, and PCR systems. A plate handler consists of a robotic arm, attached to a base unit, that moves in three dimensions (along the X-, Y- and Z-axes) controlled by an onboard software system. Microplate handlers can be programmed to perform a range of tasks, including loading and unloading microplates from lab instruments, transporting microplates between work areas, and stacking microplates for short-term or long-term storage. By reducing operator contact with plates and instruments, plate handlers protect samples from cross-contamination. Plate handlers are frequently used in proteomics research, environmental research, and academic labs.

PlateCrane EX and EX360 by Hudson Robotics

PlateCrane SciClops by Hudson Robotics

A3 - DNA Extraction Systems

Nucleic acid extraction systems use magnetic beads to isolate DNA, RNA, or other target molecules from biological samples. The complete isolation and purification process, which frequently takes between 20 and 50 minutes, includes automated mixing, magnetic bead transfer, washing, and elution steps. DNA extraction systems are optimized for use with human or animal tissue samples, whole blood samples, or plant samples.

Compare: innuPREP Nucleic Acid Isolation Kits

A4 - Microplate Dispensers for ELISA and PCR

Ideal for ELISA and PCR applications, microplate dispensers distribute volumes of liquid, often samples or reagents, into 96-well or 384-well microplates, using a reversible displacement pump, or manifold. As lab dispensers, like the Micro10x from Hudson Robotics, demonstrate fast dispensing rates (less than 20 seconds for a 96-well plate), these units are commonly used in high-throughput labs processing samples in bulk.

A5 - Hudson Microplate Washer Systems

Hudson Robotics’ RapidWash automated microplate washers quickly process standard and deep-well microplates for reuse. Microplate washers are composed of a plate deck, solution reservoir, waste vessel (with level sensor), and manifold pump for dispensing and aspirating cleaning solutions. Microplate washers are commonly integrated into high-throughput screening (HTS) workflows that include liquid handlers, plate handlers, and microplate readers.

B - Liquid Handler Capacity

(back to chart)

B1 - Low Throughput Liquid Handlers

Low-throughput liquid handlers, like the Microlab PREP by Hamilton Robotics, include a smaller deck capacity (4 - 8 positions), a pipetting range optimized for lower-volume samples (0.5 – 500 ul), and less deck space for tube racks, sealers, or shakers. Certain low-throughput systems feature single-channel pipetting heads designed to load one well at a time. Low-throughput liquid handlers are commonly used in academic research or small-scale drug discovery.

B2 - High Throughput Liquid Handlers

High-throughput liquid handlers, like the Microlab STAR by Hamilton Robotics, include a larger deck capacity (up to 24 positions), a broader pipetting range (0.5 – 1,000 ul), space for third-party device integration (such as plate readers, centrifuges, and PCR systems), waste compartments and storage cabinets. High-throughput systems feature multi-channel pipetting heads (including 8 or 12 tips) for rapid plate loading. High-throughput liquid handlers are commonly used in batch sample processing, HTS, clinical diagnostics, and drug development.

C - Liquid Handler Voltage

(back to chart)

120-volt connections are suitable for standard laboratory power outlets in the United States. 240-volt connections, common in Mainland Europe, require less current (amperage) and smaller conductors than equipment designed to operate at 120-volt.

D - Liquid Handler Plate Size

(back to chart)

D1 - 96-Well Plates

The most commonly-used microplate size, 96-well plates include the wells arranged in an 8 x 12-grid pattern. Each well has a maximum volume of approximately 300 ul.

D2 - 384-Well Plates

Used in high-throughput applications, 384-well microplates include 4 times as many wells as their 96-well counterparts. The wells in a 384-well plate are arranged in a 16 x 24-grid pattern. Each well has a maximum volume of approximately 50 ul.

E - Application-Specific Liquid Handler Features

(back to chart)

E1 - Microplate Sample Storage Cabinet

High-throughput liquid handlers, such as the Microlab VANTAGE by Hamilton Robotics, feature a side-mounted or rear-mounted storage cabinet for short-term (ambient) or long-term (refrigerated) storage of plates. The microplate transfer arm integrates with the storage cabinet to automate the loading and unloading of microplates.

E2 - Enclosed Work Area for Robotic Liquid Handling

Certain liquid handlers, like the Microlab NIMBUS from Hamilton Robotics, feature a fully enclosed work zone to protect samples and reagents from cross-contamination. Optional HEPA-filtered systems maintain an ISO class 7 environment within the work area.

E3 - Instrument Integration

Liquid handling systems, like the SOLO from Hudson Robotics, include the software, hardware, and infrastructure to accommodate third-party instrument integration, such as centrifuges, shakers, heat sealers, microplate readers, and PCR thermal cyclers.

E4 - Touchscreen Pipetting Workstations

AutoMATE 96 by Accuris Instruments include a color touchscreen panel for workflow setup, protocol programming, system calibration, and alarm optimization.

Need Help with Product Configuration?

Shop Terra Universal products online for immediate pricing or configure your components and accessories for quoting.

Contact a Terra sales specialist via phone, webchat, or email for help with configuration, large purchases, or application expertise.

F - Application-Specific Liquid Handler Features

Laboratory-Equipment.com is the laboratory specialty division of Terra Universal. For nearly 40 years, Terra Universal has served the life science, pharmaceutical, biotechnology, and medical device markets. Customers appreciate a worldwide network of reps, factory-direct support, and ready-to-ship items available from Terra's manufacturing and warehouse facilities in Fullerton, California.

Contact a laboratory-equipment.com specialist for pricing, application consulting, and same-day quotes.

Call direct: 714-459-0765 | Mon - Fri, 09:00 AM - 08:00 PM your local time

Shop and compare a wide selection of equipment for microplate handling and automated pipetting systems for a wide variety of applications including:

Automated DNA Extractors

Automated Liquid Handling

Automated Pipettors

Microplate Dispensers

Microplate Washers

Plate Handlers