Windows give us a view of the environment on the “other” side of the wall, whether looking out from an enclosed room, or looking into it. In a controlled cleanroom, windows are a source of ambient light, and help to “expand” the space, making it feel less restrictive and relieving worker claustrophobia. Practically speaking, they also allow personnel to see when the critical environment is in use, and what activities are being performed.

Windows are more complex than a simple pane of glass. Anyone responsible for wiping down a cleanroom can appreciate how troublesome nooks and crannies can be! Contaminating particles can collect on framing, sills and fasteners, complicating the sanitizing process. Terra’s stainless steel BioSafe® cleanroom windows are designed to reduce cracks and horizontal surfaces, making disinfection easier and faster.

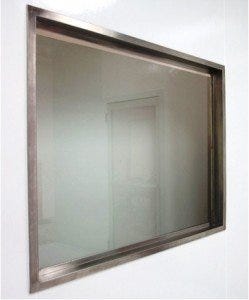

Single-Pane Windows

Single-pane window, with flush-mounting on the inner, “clean” side.

In their simplest form, stand-alone cleanrooms may be surrounded by unclassified space, with no lab or face garments required by personnel (picture a modular cleanroom within a warehouse). The enclosed space must be ISO-compliant, but the exterior doesn’t require the same treatment. Standard wall thicknesses (ranging from 3.4” to 5.5”) are many times that of a window pane (0.25” to 1”). Window frames compensate for the dimensional difference with built-in ledges: flat surfaces with sharp corners. They are ideal landing spots for airborne dust and particles, the very thing to be avoided in the controlled space.

The solution? Terra’s single-pane cleanroom windows feature a single-sided flush-mount frame. Install the window with the flush-mounted frame inside the cleanroom, and the standard frame with ledge facing the uncontrolled space. Window panes are 0.5”-thick for durability and to help maintain the cleanroom’s controlled atmosphere (thicker panes help maintain temperature for example). The flush-mounted frame is flat against the wall, with only a small, tapered protrusion that does not attract particles and is easy to wipe down.

Installation of the window is accomplished within a few minutes. Once the wall cut-out is framed, the two window frame pieces slide together; one piece is slightly larger than the other, enveloping it like a sleeve. The window pane is held firmly in place, sandwiched between the two stainless steel frame pieces. Frames are built to fit your room’s specific wall thickness.

Double-Paned Windows

Double pane window: frame is flush-mounted on both sides of the wall.

But what of multi-suite cleanrooms that maintain controlled environments on both sides of the window? Terra also designed a double-pane, double-flush window with no ledges or sills to clean. These windows feature two 0.5” window panes, increasing the temperature insulating properties. Frames in both rooms are flat against the walls, reducing troublesome cleaning.

When installing the frames for the double-flush window, the two pieces snap together (ball studs fit into pre-drilled holes), again sandwiching the two 0.5”panes of glass for a secure hold. To ensure the proper fit, Terra needs your wall thickness: it will dictate the exact depth of the window frame components.

Window Pane Materials

Five materials are used for transparent cleanroom window panes:

- Tempered glass: the ultimate clean material! Non-porous and non-shedding, with exceptional strength and clarity, glass stands up to all cleaners.

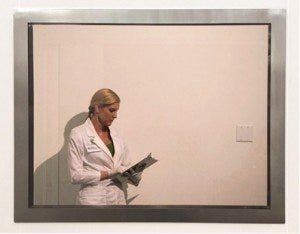

BioSafe® powder-coated flush-mount cleanroom window made of tempered glass.

- Fire-rated glass: applications involving flammable liquids or powders may require added protection of materials with UL fire-rating. Cleanroom walls made of Class A fiberglass reinforced plastic (FRP) also meet this requirement.

- SDPVC: static-dissipative polyvinyl chloride controls electrostatic discharge, and prevents particle adhesion from static charges. The dissipative layer is molecularly embedded in the plastic, so will not peel over time.

- Polycarbonate: another strong plastic material that resists damage from common chemicals. Polycarbonate is also shatter resistant

- Acrylic: this material offers strength, clarity and economy, but be careful with chemicals such as alcohol, which can damage it.

Final Thoughts

Take as much care with your cleanroom windows as you do with the other building materials and internal furnishings. BioSafe windows from Terra help maintain your ISO rating and simplify your cleaning activities. Learn more about these windows, including installation drawings and instructions by visiting BioSafe Cleanroom Windows.