Laboratory homogenizers mix, blend or pulverize chemical and biological samples to form a uniform, homogenous suspension for further analysis. More specifically, homogenizers are used to lyse cellular structures, mill environmental samples, emulsify immiscible materials, and disperse chemical compounds by particle size.

What Are Homogenizers Used For?

Used commonly in the life science, environmental science, chemical synthesis, cosmetics, and cannabis industries, homogenizers are manufactured in handheld or benchtop designs to accommodate a wide range of sample types and volumes.

A - Homogenizer Format

(back to chart)

Laboratory homogenizers utilize a number of mechanisms to blend samples into uniform mixtures. Economical, mechanical mortar and pestle units crush the sample between the container and a solid, blunt object. Commonly used to process mammalian tissues, human cells, and cryogenically frozen samples, mortar and pestle systems are easy to operate, affordable, and require little maintenance. However, these units process one sample at a time, exhibit poor reproducibility, and struggle to blend difficult mixtures. For research and development, sample testing, and production environments, four common homogenizer formats are available: bead-based homogenizers, rotor-stator systems, paddle blenders, and ultrasonic cell disruptors.

A1 - Bead Homogenizer

Bead-based homogenizers use micro-beads - made of zirconium, silica glass, or stainless steel – to pulverize bone or hard tissue samples. The beads are placed into a close micro-tube containing the sample and rapidly agitated to ensure thorough mixing. Used for organelle extraction and cell isolation, bead mill homogenizers reduce the risk of sample cross-contamination, protect operators from infectious materials, and process up to 196 samples during a single run. However, bead mill units are designed to process small individual sample volumes (up to 2.0 ml) and require thorough bead cleaning between runs.

A2 - Handheld Homogenizer

Handheld rotor-stator homogenizers include a rotating steel shaft encased within a stationary metal housing. As the rotor spins, the sample is aspirated into the area between the rotor and housing, shearing the sample before centripetal force pushes the sample through exit slots in the stator.

What are Handheld Homogenizers Used For?

Used for cell disruption, tissue extraction, particle size reduction and emulsification, rotor-stator homogenizers include interchangeable probes to accommodate samples of various sizes and viscosities. However, these systems are low throughput, struggle to process fibrous samples, and require thorough cleaning to prevent sample cross contamination.

A3 - Paddle Blender

Paddle blenders utilize mixing paddles of different sizes to rapidly homogenize liquid samples placed in blender bags. Commonly used for food microbial analysis and water testing, paddle blenders accommodate high liquid sample volumes (up to 400 ml), achieve sub-micron particle sizes, and don’t require the use of beads. However, paddle blenders are more expensive than bead mill systems, require more bench space, and necessitate daily cleaning.

A4 - Ultrasonic Sonicator Homogenizer

Ultrasonic homogenizers, or sonicators, include a generator that produces ultrasonic waves within the sample to disrupt cellular structures or tissues. The samples are homogenized through cavitation or ultrasonic waves that create bubbles as they travel through the liquid sample. The microscopic bubbles expand and then violently collapse, attacking and pulverizing the samples. Sonicators are powerful and operate at a high frequency, but generate heat, produce noise, and struggle to process dry samples.

B - Homogenizer Power Supply

(back to chart)

Ultrasonic homogenizers use transducers to convert electrical energy into mechanical vibrations. When placed into the liquid sample, the generator probe amplifies the vibrations into pressure waves that use cavitation to shear the sample. As more power, measured in wattage, is applied to the transducer, the frequency of the pressure waves increases, allowing for faster homogenization rates and thorough processing of higher volume samples. Units producing between 55 and 250 watts of power are optimal for smaller, aqueous sample sizes (up to 250 ml). Units producing over 250 watts of power are ideal for larger, viscous samples (up to 1,000 ml) and specialty applications such as nanoparticle dispersion.

C - Homogenizer Controller

(back to chart)

C1 - Analog Homogenizers

Homogenizers with aAnalog Controllers include an on/off switch, amplitude dial, and toggle switch for continuous duty or run-by-run operation. More economical than digital controllers, analog systems don’t include audible or visual alarms, data export functions or access security.

C2 - Digital Homogenizers

Homogenizers with Digital Controllers include an LED readout and push buttons to regulate power level, run time and experiment progress. Certain controllers include audible and visual alarms, data export capabilities, saved sampling programs and password protection.

D - Homogenizer Voltage

(back to chart)

120-volt connections are suitable for standard laboratory power outlets in the United States, Canada, Mexico, and South America. 240-volt connections, common in Mainland Europe and throughout Asia, require less current (amperage) and smaller conductors than equipment designed to operate at 120-volt.

E - Ultrasonic Homogenizer Frequency

(back to chart)

Ultrasonic homogenizers, or sonicators, produce ultrasonic waves at two common frequencies: 20 kHz (20,000 cycles per second) or 40 kHz (40,000 cycles per second). As the frequency produced by the generator probe increases, the agitation rate of the sample also increases.

What Are the Differences Between 20 kHz and 40 kHz Homogenizers?

Sonicators operating at a frequency of 20 kHz are optimal for aqueous samples diluted in water or PH-neutral buffer whereas sonicators operating at 40 kHz are ideal for viscous samples.

F - Special Homogenizer Features

(back to chart)

F1 - Pulsed-Mode Operation

Pulsed-mode operation, or pulsed-mode mixing, toggles between short cycles of high-intensity sonication and longer cycles of rest. The duration of the sonication and rest period are programmed by the user. Pulsed-mode operation is optimal for heat-sensitive samples as the rest periods allow for heat dissipation to prevent over-warming of the sample.

F2 - Refrigerated

The Next Advance BulletBlender uses a refrigerated coil to cool samples housed in microtubes down to 4°C for processing and temporary storage of temperature-sensitive samples.

F3 - Cup Horn

Cup horns provide indirect sonication and act as an ultrasonic water bath, allowing samples to be processed in sealed tubes to prevent cross contamination and protect operators from exposure to hazardous materials.

F4 - Glass Cooling Cell

Glass cooling cells allow for batch liquid samples to be processed at below-ambient temperatures. After the cooling cell is placed in an ice bath, the horn or micro-tip is inserted into the sample to circulate the solution. The cooling cell provides optimal surface area for heat transfer to protect delicate samples from overheating.

G - Homogenizer Probe Diameter

(back to chart)

The optimal probe diameter is dependent upon the sample tube or vessel size and the volume of the sample. Probes of 0.125” diameters are ideal for 1 ml to 15 ml sample volumes. Probes of 0.25” diameters are optimal for 10 ml to 50 ml sample volumes. Probes of 0.5” diameters are ideal for 20 ml to 250 ml samples. Probes of 0.75” diameters are optimal for 50 ml to 500 ml samples.

H - Sonicator and Homogenizer Sample Capacity

(back to chart)

Small-throughput ultrasonic homogenizers are designed to process single samples at a time while high-throughput models can accommodate up to 192 samples during a single run.

Where Can I Buy Lab Homogenizers and Sonicators Online?

Laboratory-Equipment.com is a specialty division of Terra Universal. For nearly 40 years, Terra Universal has served the life science, pharmaceutical, biotechnology, and medical device markets. Customers appreciate a worldwide network of reps, factory-direct support, and ready-to-ship items available from Terra's on-shore manufacturing and warehouse facilities in Fullerton, California.

Shop lab homogenizers online for a wide variety of pharmaceutical, laboratory, life science research, and analytical environments. Terra specialists are able to provide support and expertise among many applications including life science research, drug discovery, material testing, wafer production, and wet chemistry.

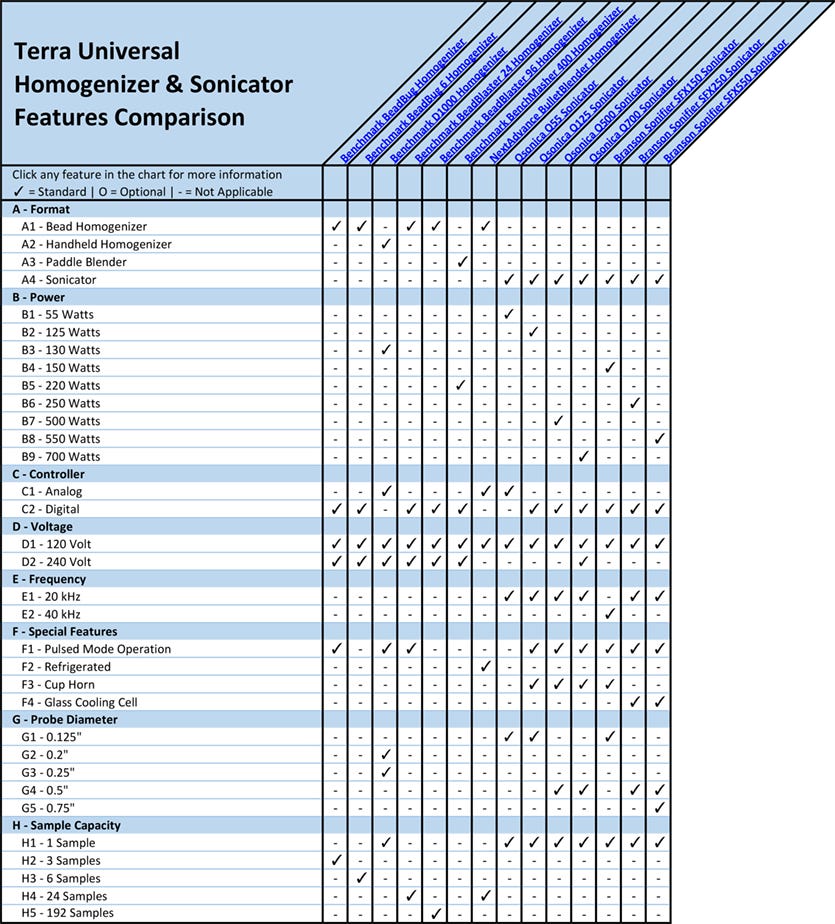

Compare Homogenizers By Brand

U.S. Customer Service

Contact a Laboratory-equipment.com specialist through web chat, email, or phone for pricing or a same-day quote.

Email: [email protected]

Phone: (714) 578-6016

Try before you buy!

DEMO MODELS AVAILABLE

Contact us for Demos, Samples, Brochures and more.

EMAILMon - Fri, 5:30am - 5:30pm PST